How cheap technology is costing us dear

Squeezing suppliers can be a nasty business

It's a great time to be a gadget geek. From wireless routers to Windows PCs, smartphones to sat navs, our technology has never been smarter – or cheaper.

The internet is a hardware heaven where you can pick up enormously powerful bits of kit for tiny amounts of money. It's just a shame about the whole economic damage, worker exploitation, environmental catastrophe side of things.

Cheap technology isn't as cheap as you might think. When something's designed to a particular price, compromises have to be made. Those compromises aren't just in the design, although of course you can't expect Porsche quality at Primark prices; they're in every part of the technology company's business from the factories it uses to the way it provides technical support. Typically, cheap technology means cutting every possible corner to make the price as low as possible.

What happens when you cut one corner too many? Let's ask Dell, the pioneer of ultra-cheap PCs, who managed to ship 11.8 million faulty – and potentially explosive – PCs between 2003 and 2005

The problem was with dodgy capacitors, manufactured from a stolen – and, it turned out, incorrect – formula. Writing in The Independent in 2003, Charles Arthur noted that Dell was aware of the compromised capacitors, and interviewed Dennis Zogbi of Paumanok Publications, who said: "People want Western quality and Chinese prices. Well, you can't have both."

Dell thought you could.

Dell's business was – and is – based on what the New York Times describes as "limiting its inventory and squeezing suppliers", but it's possible to squeeze too hard. Cheap technology is a balancing act between price and quality control, and it seems that Dell lost its balance: the NYT reports that Dell suffered far more from bad capacitors than its rivals.

Get daily insight, inspiration and deals in your inbox

Sign up for breaking news, reviews, opinion, top tech deals, and more.

Despite internal tests finding that Optiplex desktops might have a failure rate as high as 97%, Dell didn't want an enormous and enormously expensive product recall, so it had a brilliant idea: it would blame its customers for the faulty computers.

According to the NYT Dell told the University of Texas its computers were failing because staff were "making them perform difficult math calculations."

BAD CAPACITORS: This Dell customer's capacitors don't look too clever. In total, Dell shipped 11.8 million machines with capacitors likely to fail

Still, at least if your Optiplex exploded you'd be able to speak to somebody knowledgeable about it. Wouldn't you? Nope. Dell was one of the first tech firms to outsource its customer service and technical support to Bangalore, and while the results were so bad and unpopular that Dell very quickly reinstated US-based support for its lucrative corporate customers, the idea stuck. These days, cheap kit means outsourced or online-only, irritating and inadequate technical support. You get what you pay for.

Unemployment and unhappy workers

Decent wages, employee healthcare, pensions and other benefits aren't compatible with cheap kit.

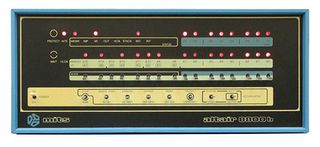

Because of those costs, Western technology firms have been outsourcing assembly work since the 1980s. Incredibly, there are fewer people making computers in the US now than there were in the 1970s: writing in BusinessWeek, former Intel boss Andy Grove says: "manufacturing employment in the US computer industry is about 166,000, lower than it was before the first PC, the MITS Altair 2800, was assembled in 1975."

OUTSOURCED: There are fewer people employed making computers in the US today than there were when this was cutting-edge tech

People still make our gadgets, of course. They just don't do it in the West. From Xbox 360s to iPhone 4s, many of our devices are put together in China. China's biggest electronics subcontractor, Foxconn, has around 800,000 employees and adds 100,000 more every year; Grove says that Foxconn employs "more than the combined worldwide headcount of Apple, Dell, Microsoft, HP, Intel and Sony."

In total, an estimated 1.5 million people work in Asian assembly plants. For every Western employee a technology firm has, there are ten Asian assembly workers putting its products together – often on very low wages and in poor working conditions.

By outsourcing the assembly work, we're missing out on money that would otherwise be spent locally. With no factories here, there are no machines for local firms to service, no subcontractors providing key components, no armies of hungry workers for the local shops and take-aways to feed, no pay packets injecting cash into local businesses from cake shops to car dealers.

For now it's Foxconn's turn in the sun, but that won't last forever. The same things that eventually made the US too expensive for tech firms – rising wages, good working conditions and organised labour - are starting to happen in China, too.

After a wave of suicides led to unwelcome foreign attention, Foxconn massively increased employee wages; meanwhile, a wave of strikes in China is forcing other firms to pay more, too.

That's good and bad. It's good if you're getting a pay rise, but it's not so good if your employer decides to up sticks to somewhere cheaper. And there is always somewhere cheaper. Right now that's inland China, where living costs and therefore wage expectations are lower than in coastal regions, so firms are moving there.

In the longer term firms may leave China altogether and go where labour costs are lower: South America, perhaps, or Vietnam. They're already thinking about it.

Carcinogens, conflict and child labour

Tim Hunt is with Ethical Consumer magazine, which hopes to make us think again about cheap, disposable technology. As EC reports, the gadgets we dump often end up in places like Indonesia, where "those processing the waste are often overworked (up to 18 hours per day) and underpaid, and the use of child labour is common… often unprotected, workers use fire and mercuric acid baths to extract the precious metals. Burning releases dioxins - some of the most toxic compounds on Earth – while the acid residue contaminates drinking water."

"There are also problems around the mining of natural resources, from the Congo for instance," Hunt told TechRadar. "Here the trade in metals has been blamed for fuelling the conflict that has raged there for several years."

WASTED: Disposable technology doesn't always end up in recycling plants. E-Waste has become a global problem [image credit: CP on Flickr]

As technology becomes increasingly fashion-driven, this year's must-have gadget quickly becomes unwanted – and the move to mobile-based computing means things are speeding up. Where a PC has a useful lifespan of three to five years, we replace our mobiles every 18 months.

"It is clearly worse than it was 20 years ago because there is just more technology around and things are progressing so quickly," Hunt says. "If there is a closed loop where all products and materials are recycled then it shouldn't be a problem. Unfortunately, even with the new EU regulations, much of the waste finds its way into the landfills of poorer countries."

Greenpeace wants to see tech firms eradicate toxic chemicals altogether. "The issue of toxicity is overarching," it says. "Until the use of toxic substances is eliminated, it is impossible to secure 'safe' recycling."

Writer, broadcaster, musician and kitchen gadget obsessive Carrie Marshall has been writing about tech since 1998, contributing sage advice and odd opinions to all kinds of magazines and websites as well as writing more than a dozen books. Her memoir, Carrie Kills A Man, is on sale now and her next book, about pop music, is out in 2025. She is the singer in Glaswegian rock band Unquiet Mind.

Most Popular