Best sublimation printer of 2024

The perfect printers for imprinting fabric and hard surfaces by dye sublimation

The best sublimation printers make it possible to print graphics and logos onto mugs and textiles using inkjet technology, transfer paper and a process called dye sublimation. Their ability to fix detailed digital images onto apparel in a way that won’t crack or wash away is making waves among start-ups in the clothing industry, while other businesses are finding sublimation printers ideal for adding adverts and corporate logos to plastic, glass or any other sublimation-friendly surface. Whether you’re a crafter looking to customize your own tee-shirt at home, or a business looking to sell quantities of printed merchandise, you’ll find the best sublimation printers at a variety of price points on this shortlist.

As TechRadar Pro’s resident printer specialist, I’ve tested over a hundred printers, from the best printers for the home and office to models for for imprinting fabric and hard surfaces by dye sublimation. I've rounded up my top sublimation printers to suit a variety of users, from hobbyist to professional. The best overall sublimation printer in my view is the Epson SureColor SC-F100 (F170), listed below. But if you need a higher specification, there’s also the Mimaki TS100-1600.

The best sublimation printer of 2025 in full:

Why you can trust TechRadar

Best sublimation printer overall

1. Epson SureColor SC-F100 (F170)

Specifications

Reasons to buy

Reasons to avoid

This isn't just the best Epson sublimation printer, but our pick for best printer for sublimation overall. Just about anyone can use this machine, offering the easiest printing method on fabric and other suitable sublimation surfaces. You fill the ink tanks with the unique ink provided in the box and print your design onto special transfer paper as you would with a regular inkjet printer. Transfers printed this way can be applied with a heat source to your chosen surface with reliable results. You get four 140ml T49M bottles of ink (C, M, Y, K), widely considered the best dye for sublimation. The printer is conveniently compact, based on Epson’s excellent EcoTank line. Though it lacks a display, it’s easy to use with the accompanying software for Mac and PC.

Best sublimation printer for businesses

2. HP Stitch S500

Specifications

Reasons to buy

Reasons to avoid

HP’s high-tech dye-sub printer prints on both transfer paper and directly onto fabric using the same innovative water-based dye-sub ink. The Stitch S500 is ideal for businesses with high print demands because at around 110 m² per hour, it prints quickly and can be automated to work through the night without monitoring. There’s plenty of room for ink and it takes large rolls of paper or fabric, while the thermal printheads can be easily replaced with one hand and recycled. Small fans blow the emerging print job to dry the ink before it is rolled and there’s a touchscreen panel for ease of use. If you need a hardworking dye-sup printer with all the latest features, this is it.

Best sublimation printer for beginners

3. Epson SureColor F570 Pro

Specifications

Reasons to buy

Reasons to avoid

Epson’s step-up dye-sub printer includes everything you need to print on fabric and hard surfaces right in the box. It’s a large-format inkjet printer and can handle all sizes of transfer paper from Letter/A4 up to 24-inch wide rolls. The cutter is built in and it ships with two 140ml bottles of ink for all four colors. This Pro edition also comes with professional software, Epson Edge Print Pro. With that and the large color touchscreen interface, this is dye-sub printing made easy, while its precisionCore MicroTFP printhead ensures the highest print quality.

Best sublimation printer for crafting

4. Sawgrass SG500

Specifications

Reasons to buy

Reasons to avoid

Sawgrass specializes in sublimation and its latest entry-level model makes the process both simple and affordable. It’s a desktop printer designed to print specially formulated inks onto transfer paper of any size up to Legal Wide (8.5 x 14 inches). It offers high-resolution inkjet printing using the company’s own UHD inks, which work with a wide variety of substrates from polyester fabrics to polymer-coated rigid media such as metal or glass. It comes with everything you need to get started in the box, including a 21ml starter set of ink, Sublisure A4 Paper (100 sheets) and Sawgrass Software.

Best sublimation printer for professionals

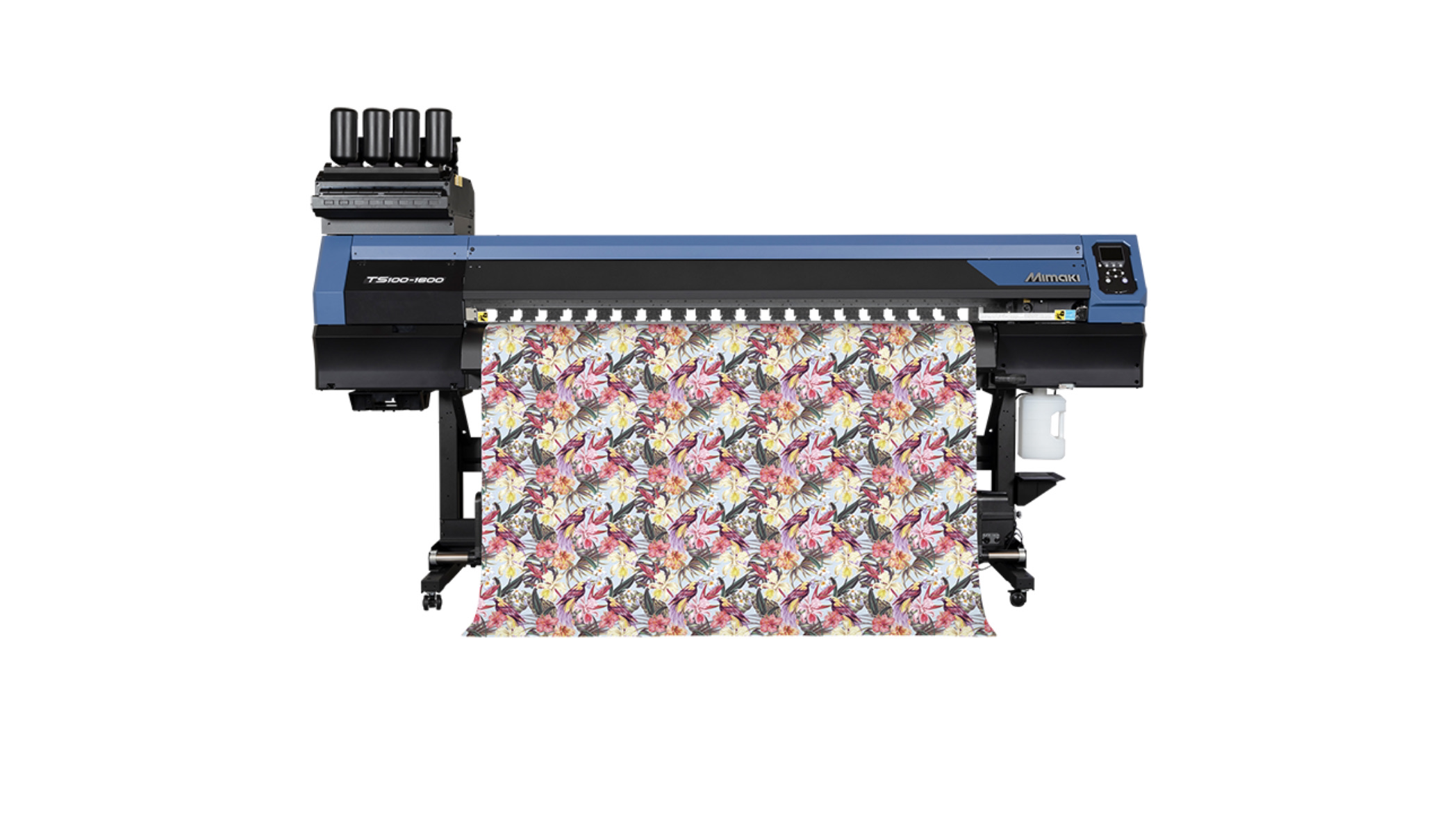

5. Mimaki TS100-1600

Specifications

Reasons to buy

Reasons to avoid

This wide-format dye-sub printer can accept 64-inch rolls of sublimation transfer paper, which is the most common size in the fashion world. This latest edition prints quickly in full four-color mode at 753 square feet per hour. The one-liter tanks hold enough sublimation ink to set it to work on a long print run while you design your next detailed and vivid design. There’s no inbuilt touchscreen interface, but this printer ships with full software so you can control it from your computer. With 900dpi print quality, this relatively affordable machine will suit startups and SMBs in the textile industry.

Best wide-format sublimation printer

6. Epson SureColor SC-F6400

Specifications

Reasons to buy

Reasons to avoid

The Epson SureColor SC-F6400 is a dedicated dye-sub printer from Epson that can take 44-inch rolls of transfer paper for imprinting large textiles, or creating lots of smaller transfers at once. The package includes everything you need to start sublimating (except the heat press) from dedicated dye-sub inks to a maintenance kit and sublimation software. It’s using Epson’s new PrecisionCore MicroTFP printhead to produce large high-resolution images on transfer paper with less chance of nozzles clogging. The ink packs are 45 percent larger than the previous model so there’s less down time, while the large touchscreen interface makes it easier to use.

Best sublimation printers: Frequently Asked Questions

What is a sublimation printer?

Sublimation printers can print onto cloth and hard surfaces like ceramic, which has proved to be a real game changer for the textile industry. We sometimes call them to transfer sublimation printers because instead of printing directly onto fabric or ceramic, these machines apply sublimation ink to transfer paper which is then applied to the desired surface using heat and pressure to sublimate the ink.

Sublimation is the transition of a solid to a gas without it passing through the liquid state, and we’re talking here about solid ink particles held in suspension. When heated into its gaseous state, the sublimation ink can penetrate the fabric or substrate and bond with its fibers before returning to a solid form. Yes, dye sublimation inks are quite different from ordinary printer ink, so you can’t use your existing paper printer for dye-sub printing. However, it is possible to convert an inkjet printer into a sublimation printer because the only critical difference is the ink.

How does a sublimation printer work?

Sublimation printers do not print directly onto the garment or mug but onto a sheet of special sublimation transfer paper using standard inkjet technology. These machines are the same size as your average home or office printer so that they can be loaded with A4 or Letter-size sheets. That means you can create your design, logo, or motif on your computer and print it out the usual way. The critical difference is how the sublimation ink temporarily bonds with the transfer paper. This printout should be a mirror image because it will be reversed again when applied to the object you want to print on. It may also look dull, but when we use heat and pressure to fix it onto our fabric or substrate, the design should look as bright and detailed as it did on our monitor. It’s important to note that sublimation ink only bonds with man-made fibers, so if you prefer natural cotton shirts, choose one with a blend of at least 50% polyester content.

Do I need a heat press to go with my new sublimation printer? Yes, although sometimes we use a regular iron to transfer our dye-sub designs onto our tee shirts. To make the ink in the transfer paper turn from solid to gas (sublimate), we must raise the temperature to around 400°F for at least 40 seconds while applying about 40psi of pressure. A heat press explicitly designed for dye sublimation will make this part of the printing process much more manageable. These products vary from inexpensive portable devices or presses expressly designed to hold mugs to the high-pressure heat transfer machines the industry uses to imprint larger pieces of fabric.

What can I do with a sublimation printer?

Thanks to sublimation, we’re no longer limited to printing on paper. We can use sublimation to print on any polymer or polyester substrate. So that could be fabric, plastic, ceramic, metal, or glass. Dye sublimation is perfect for printing patterns, logos, and pictures on tee shirts, for example, so long as the fabric contains man-made fibers. Because the ink can penetrate the material as a gas before bonding permanently with the polyester fibers as a solid, the design is permeant too. The ink won’t stiffen on the surface, scratch off, or fade in the wash because it has become part of the fabric.

Sublimation is also a great way of printing on pens, mugs, or badges, and the process is much the same, so long as you choose blanks (printable white objects) with a suitable substrate coating. When heated, the gaseous ink particles from your printed transfer paper bond with the substrate coating your mug, and the results should look no less vibrant than a glossy photo print.

What's the main differences between a sublimation printer and a normal printer?

Sublimation printers often look like paper inkjet printers because they only need to print onto transfer sheets and not directly onto mugs or garments. The real difference is the type of ink used. Epson’s sublimation printers are no different from their equivalent office and home printers other than the packaging and bundled ink.

We can easily convert new refillable ink tank printers into sublimation printers by filling them with sublimation ink instead of regular dye or pigment-based ink. Just ensure there is no ordinary ink in the tank already because the two types of ink will not mix. We have also seen kits for converting cartridge-based office inkjet printers into sublimation printers. These kits include the syringes to fill empty cartridges with sublimation ink and convert your cartridge printer into a refillable CISS (continuous ink supply system) printer.

Dedicated sublimation printers come with sublimation ink and transfer paper in the box, and some also include software to help you design and print your project. Sublimation printers usually publish a complete color design with four base colors, just like a paper printer. Still, more expensive models may mix six or eight base colors to achieve superior color fidelity, but they nearly always use bottled sublimation ink rather than cartridge ink.

Don’t confuse sublimation printers with DTG (direct-to-garment) printers, which offer an alternative way of printing on textiles. DTG printers are considerably more significant so that fabric can be fed into the machine, where the ink is applied directly to the cloth without sublimation. DTG has the advantage of being able to print on natural fibers like cotton and bamboo, though they cannot print on hard surfaces.

How to choose the best sublimation printer for you

To help when choosing which sublimation printer is best for you, these are a few factors to consider.

Firstly, ask yourself what you will be mainly printing. An A4-sized sublimation printer will be fine if you need the best printer for t-shirts, mouse-mats, and other small projects. This is the most common format and the least expensive. For imprinting more oversized garments, or rolls of cloth, you’ll want the best large format printers for dye sublimation, which will cost more. How frequently will you print? For a business with high production in mind, the size of the ink tanks and the sublimation ink cost are factors. For the hobbyist, ink tank size will not be an issue. While you may not need the fastest printers, the print speed, usually quoted in PPM (pages per minute), could also be a consideration.

The number of ink tanks built into the printer will significantly affect print quality. Four colors, CYMK, is all you need to mix the rest, but a printer using six or eight sublimation inks will achieve superior image quality of sort you'd expect from the best photo printers.

For those specializing in textiles, the bundled software is another feature to consider because, in some cases, the manufacturer’s PC software can help set the colors to suit the fabric best.

How we test the best sublimation printers

Being the senior printer editor at TechRadar Pro means I get to test all the new printers, from the best inkjet printer to the best laser printer, and I’m always improving my methodology. The process starts right from the unboxing and initial set-up, which is timed. If there’s a problem with unsustainable packaging or a baffling user manual, I’ll call it. If it’s a pleasure to use, that’ll be reflected in the final score too. I always test both wired and wireless connections and explore the various remote printing companion apps offered by brands such as HP and Epson as these often enhance the user experience.

For the performance tests, I have a folder of test cards, photos and text documents designed to assess detail resolution, contrast, color accuracy and gamut. In the case of dye sublimation, I have a range of designs to print onto a range of fabrics.

For the best sublimation printers shortlist, I sought out every dye-sub model worldwide, including models I have not tested, and compared their specifications, features, and price. These sublimation printers are all current models sporting the essential functionality for sublimation printing and each model has proven capable of high-quality sublimation at a competitive price.

You can find out more about our comprehensive testing process in our guide to how we test, review, and rate printers on TechRadar Pro.

Get in touch

- Want to find out about commercial or marketing opportunities? Click here

- Out of date info, errors, complaints or broken links? Give us a nudge

- Got a suggestion for a product or service provider? Message us directly

- You've reached the end of the page. Jump back up to the top ^

Are you a pro? Subscribe to our newsletter

Sign up to the TechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

Jim has been evaluating printers for more than twenty years and has, to date, written over a hundred reviews for TechRadar Pro. From pocket printers to industrial dye sublimation, Jim has been there, run the tests and printed the t-shirt. His expertise extends to consumables (paper, ink, toner) and his printer buying guides make it easy to compare these essential peripherals.

- Steve ClarkB2B Editor - Creative & Hardware