3D printing breakthrough could make racing cars or bikes go faster

Fiber composite parts from a way more affordable 3D printer

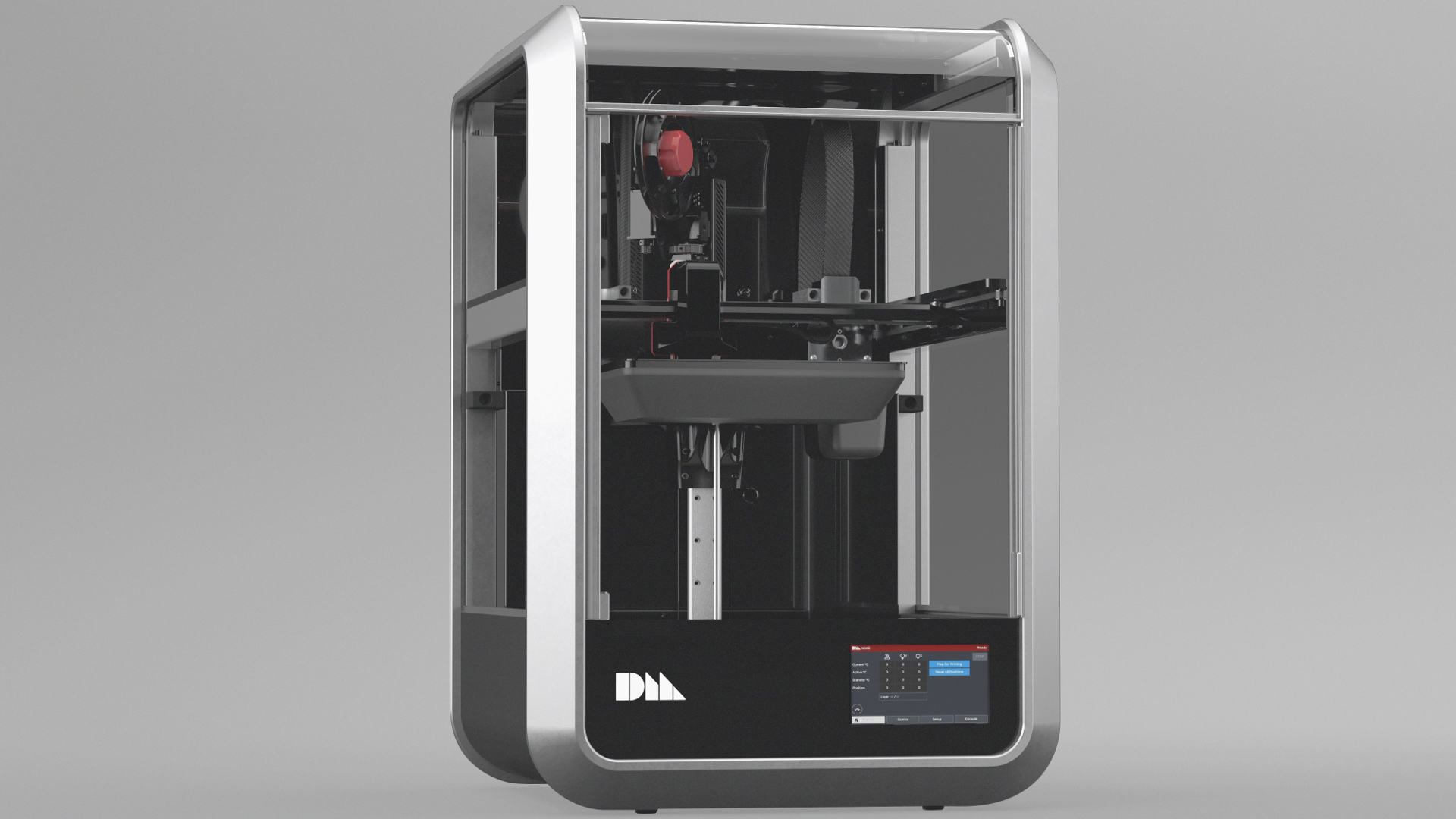

Desktop Metal has introduced Fiber, claiming that this is the first 3D printer which delivers ‘industrial fiber performance’ in a desktop printer which is far more affordable than traditional solutions.

This innovative 3D printer makes use of a new process called micro automated fiber placement (micro AFP) which allows for the printing of high-resolution parts with industrial-grade continuous fiber composite materials.

- 3D printing could be used to print human tissue

- These 3D-printed houses are made with a dirt cheap material

- These are the best 3D printers of 2019

These are objects with a high level of strength and rigidity – the parts produced are twice as strong as steel, yet only 20% of the weight – which would traditionally require AFP systems that cost in the millions.

Desktop Metal’s Fiber is far more affordable (we’ll come on to pricing shortly) and is also capable of printing much faster, to boot.

Ric Fulop, CEO and co-founder of Desktop Metal, explains: “For the first time, Fiber printers combine the material properties of high performance AFP continuous fiber materials with the affordability and speed of a desktop 3D printer.”

Specifically, Fiber miniaturizes AFP tech, combining it with Fused Filament Fabrication and employing a robotic tool changer architecture (with the ability to store up to four tools, including printheads for different materials, or future expansion with functionality such as automated in-process inspection).

Myriad applications

Uses for such 3D-printed parts are highly diverse and include components for electronics, cars, planes and so forth, and particularly where lightweight but strong materials are needed such as racing cars or bicycles, or indeed wheelchairs.

Are you a pro? Subscribe to our newsletter

Sign up to the TechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

Will Turner, President of Turner Motorsport, enthused: “Weight is everything in racing. Being able to replace critical metal components with 3D-printed continuous fiber means we can retain the strength of metal while lowering the overall weight of the car – making it even faster and more competitive.”

The Fiber printer is set to ship in the spring of 2020 and pre-orders are being taken, but note that the product is provided as a hardware-as-a-service subscription plan, of which there are two variants.

The cheaper tier starts at $3,495 per year, and allows for the printing of nylon-based continuous fiber materials, with the more expensive one – which adds the ability to work with PEEK and PEKK-based materials – starting at $5,495 annually.

Darren is a freelancer writing news and features for TechRadar (and occasionally T3) across a broad range of computing topics including CPUs, GPUs, various other hardware, VPNs, antivirus and more. He has written about tech for the best part of three decades, and writes books in his spare time (his debut novel - 'I Know What You Did Last Supper' - was published by Hachette UK in 2013).