The technology of the Tumbler - how Britain made the Dark Knight mobile

Behind the scenes with the latest Batmobile

But it wasn't just the bespoke suspension that caused problems: the braking of such a vehicle needed to allow it to turn around the tight corners of the city scene, something most stunt cars aren't great at doing.

Holmes said the Batmobile team needed to come up with some ingenious ways to make this happen:

"The brakes were somewhat… reluctant… to work, shall we say. The brief was for the Tumbler to be able to do handbrake turns and stuff like that, so we rigged up a separate hydraulic brake so you could lock the rears up."

Given that five full-size Tumblers were made, the speed with which they were created was impressive.

"The feeling was one of 'let's go" when making these things," said Holmes. "We made a working prototype in six weeks, and a further six months to build five cars.

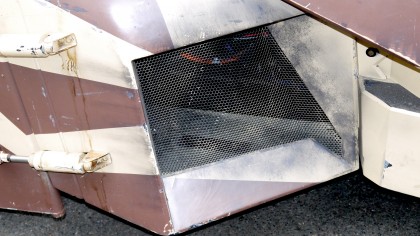

"We had a bodywork department, working on the glass fibre stuff, but our first prototype was a shell, with no bodywork on it.

"We made five cars in total, although we've only got four left. We blew one up, there's one left in the States and the other three are in Britain. We made one black car, and the rest are all camouflage."

Get daily insight, inspiration and deals in your inbox

Sign up for breaking news, reviews, opinion, top tech deals, and more.

"One of our guys, Jim, designed the chassis, but the rest of the team took other elements: one guy worked on the suspension, one on the axle. We actually broke it several times during production to make sure it didn't break on the day… but then again we had five cars so there was always a backup!"

Although Holmes proudly states that none of the cars failed, broke or even refused to start, he did say they pushed it a little harder in testing to find the limits in other ways.

"We had to test the Tumblers to destruction, so we did blow an engine up; while doing a jump we broke the handling, so we beefed that up until finally we got a machine that would do what Nolan wanted it to do."

The great thing about the Batmobile project is that the finished products are actually driveable – although visibility is poor. The cars have even been used as pace cars in US NASCAR racing – and Holmes admitted that he and his team still try out the vehicles when they get the chance.

"You can't see much out of it when you're driving at speed, but when we're going to events with these cars I normally drive and Jim directs me.

"But on the track [the Tumbler] is very predictable, allowing you to oversteer in the wet for instance, so you can get the back to step out and it comes back in just fine. It's really good fun to test - I managed 90mph down the straight, but it will do over 100mph if you have the space."

Given that each of these Batmobiles costs nearly £200,000 to produce, and the whole project cost millions overall, it's impressive that the desire to create real, working cars was maintained through undoubted pressure to save money and use CGI.

But once you've heard the ear-splitting roar of the Tumbler engine, you can't help but feel more than a little glad that the Batmobile made it into real life… just make sure you're not standing too close to the back of it.

Gareth has been part of the consumer technology world in a career spanning three decades. He started life as a staff writer on the fledgling TechRadar, and has grew with the site (primarily as phones, tablets and wearables editor) until becoming Global Editor in Chief in 2018. Gareth has written over 4,000 articles for TechRadar, has contributed expert insight to a number of other publications, chaired panels on zeitgeist technologies, presented at the Gadget Show Live as well as representing the brand on TV and radio for multiple channels including Sky, BBC, ITV and Al-Jazeera. Passionate about fitness, he can bore anyone rigid about stress management, sleep tracking, heart rate variance as well as bemoaning something about the latest iPhone, Galaxy or OLED TV.