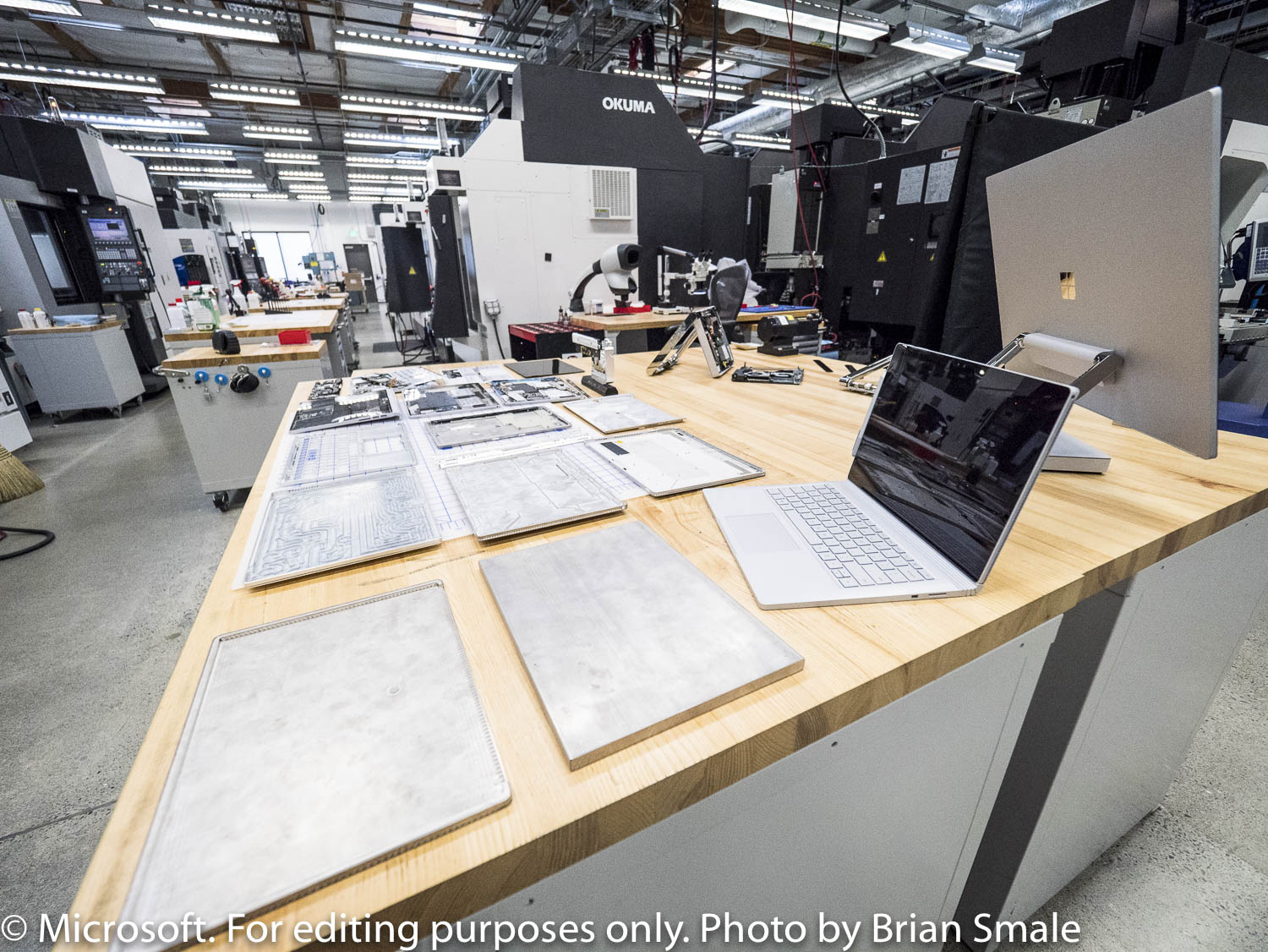

Believe it or not, what you see above is where all of the latest Microsoft Surface devices were born.

Building 87 looks a little rundown and so unassuming that you wouldn’t even think it was part of Microsoft’s sprawling Redmond, Washington campus. But, despite its meek outward appearance, the Microsoft Advanced Prototyping Center (APC) that lies inside is one of the most well-equipped fabrication labs we’ve ever seen, and it’s staffed by some of the company’s most brilliant minds and diverse trades.

We caught up with John Haley, who manages the APC, to pick his brain about how the center operates on a daily basis and all the work that goes into developing Microsoft’s Surface devices.

“I jokingly call this the maternity ward for product and, for me, it really is,”Haley chirps. “I get to see all these babies get born, and it’s amazing.”

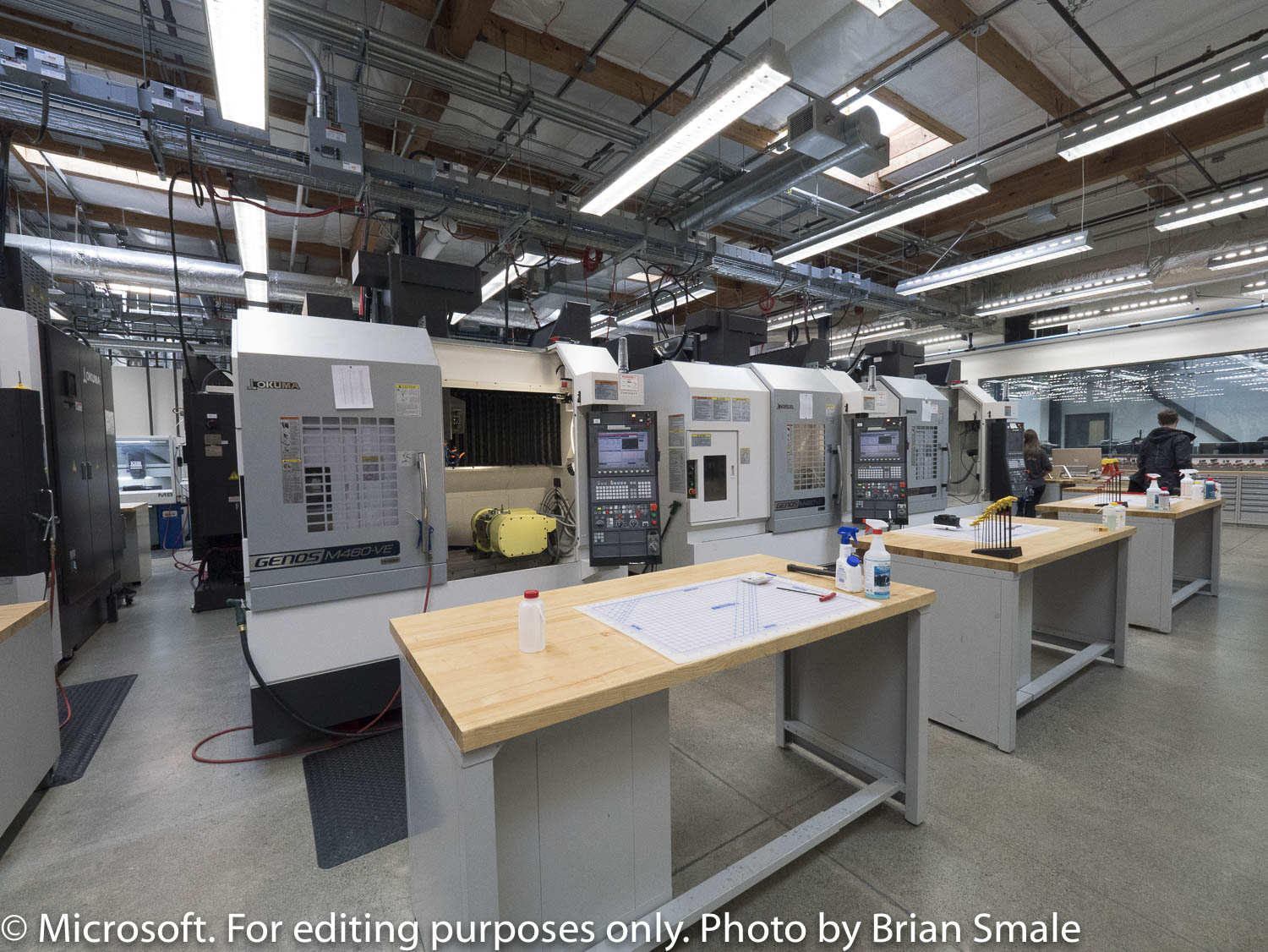

Of course, the labor required to create a Surface device is intensive, which is exactly why the APC is well equipped with every type of machinery you can think of. During our tour of the APC, Haley rattled off the list of tools in the lab that included, MIG welders, TIG welders, CNC lathes (basically a machined-controlled dremel), CO2 and UV laser cutter, a 50,000 psi water jet, spun EDM, a dye sublimation printer used to color fabrics, a book-making machine and, of course, many 3D printers – and that’s just a fraction of the equipment.

Haley boasts that the APC team has a lot of crazy tools and, while they don’t use all of them every day, when they do need them, they need them right there and then. This extends to the insane development speed that the hardware development team operates at.

“Most of our prototypes I would say are built in days, not weeks,” Haley explains. “We’ll build something, we’ll back engineer it, look at it and come back to say we like this or don’t like this, let’s build another one, and we’ll just keep building and iterating. We end up going back and forth hundreds of times until it’s right, we really do.”

Get daily insight, inspiration and deals in your inbox

Sign up for breaking news, reviews, opinion, top tech deals, and more.

Haley recalled the Surface Studio started as a big desk prototype that was rebuilt over 50 times.

“We just kept rebuilding it, and it was all about getting that seamless two finger touch on the device,” Haley says. “So, you can place your fingers at the top of the Surface Studio and put it into drawing mode really seamlessly.“

With 3D printing prototypes alone, Haley says the APC produces 200 parts a day in a room with more than a dozen fabrication machines whirring away. Just two days ago, as of this writing, the lab produced 263 unique parts in a single night.

“Everyone is using those 3D printers to figure out what’s next, find the opportunities, the problems of new products and figure them out soon and fast,” he says.

It’s the little things

At the Advanced Prototyping Center, Surface devices are conceived from an idea, built a million times over and perfected before heading off for factory production. As Haley explains it, they essentially produce devices from scratch that prove 95% of what Microsoft is going to do in production.

Now, as for how the prototyping process starts, Haley explains that it can happen in a variety of ways, from full-blown CAD software models with detailed specifications to something as rudimentary as a rough whiteboard sketch. However, the real process comes down to building, collaborating and iterating on prototypes.

We’ve seen plenty of exploded models of Surface Laptop, Surface Book and Surface Pro over the years at Microsoft’s announcement events, but prototyping at the APC goes many steps smaller. From the frame to Surface Book’s Dynamic Fulcrum hinge to a tiny specialized screw, everything is developed at the APC.

“We build both a lot of mechanical prototypes anytime something has to move or pop or twist or any of that kind of stuff we’ll build them until they’re perfect, he says. “[With] Surface Book for instance, [we asked] how much friction is in the hinge and is it reliable. These are the really important answers you want early in the product cycle.”

The mechanics and build quality are just one part of the equation for Microsoft’s hardware. Haley and the team at the APC also care a great deal about the aesthetics of devices like the Surface Laptop.

“Also anytime there’s color or finish on a product we build a lot of those prototypes too,” he says. “It’s critical for us to tune hand feel, color, gloss levels and all those things until they’re absolutely perfect.”

To that end, Microsoft is one of the few companies that color match the fabric and metal of their products. The reason why the Surface Laptop metal chassis and Alcantara keyboard deck blend together is thanks to a three-man team of painters at the APC with an eye for color.

“They work with our industrial design staff every day to tune in those colors and make them exactly what the designers want.” Haley expounds. “It sounds easy, but it’s actually a long iterative process, so we spray and print a lot of color.”

Haley explains tuning colors is complicated because people are emotional, using the example that designers will love one shade of red, but it’s too aggressive, or a blue is too sensitive. These are things computers can’t understand, and so people help read into that – of course, there are always disagreements.

“It’s those really subtle things people don’t really pick up on but we obsess about,” Haley quips.

Meteoric rise

Building 87 hasn’t always been the home of Microsoft’s APC. According to Haley, the APC was located in a smaller studio roughly 5,000 square-feet when he first joined six years ago to work on the first Surface tablet.

“Right after that we started planning that next phase [of Surface] and moving into Building 87, where we’ve almost been there for 3 years,” he says. “September will be our third year at Building 87, when we moved in we went from 5,000 square feet to roughly 25,000 square feet.”

The space was empty when Haley and his team first moved in, but in just two short years and change the APC has run out of room as the lab took on more equipment with Surface becoming a huge deal for Microsoft.

“The change was pretty much overnight and amazing,” Haley recalls. “We went from a handful of CNC machines to having 26 CNC machines in Building 87.”

And, it’s not the just the number of machines that have grown in quantity. The APC staff has also since ballooned from just five people to a staff of over 50 individuals. There are a wide range of disciplines at the Microsoft hardware lab, including industrial designers, mechanical engineers, traditional model makers, toy makers and even a special effects artist who worked on The Walking Dead.

“We have such a broad reach of capabilities at the APC, and that’s because of the people too. The people here have different things that they’re really, really good at,” Haley expounds. “Having all these different kinds of people that I can bring together into a room and say I have this problem, what do you think? I’ll get a half a dozen different ideas right away.”

“My special effects guy is awesome at complicated mechanisms,” he says. “When you do special effects, you have to make things move and rotate in different ways, and sometimes it’s really simple stuff, but he’s really good at creating complex mechanisms. And then I have full blown mechanical engineers that I can take a really complicated problem and they can make it really simple.”

“It’s really amazing how we kind of come together and sometimes the ideas are totally different. You can have two totally different ideas and they’re both valid, so you have to talk through it as a group and figure out what’s the best way to run at it. It’s really fun how that works.”

Haley prides himself with fostering a collaborative environment in the APC that doesn’t have enclosed offices but tables for groups. There’s also fairly strict rule on making sure that everything in the lab stays at around waist level, so everyone can see where each other is in the office and not have to chase anyone down.

“You walk in here in the morning and it’s already on fire, it’s electric, people are running around and they’re coming up with that next great idea,” Haley describes. “Everyone is together, they’re collaborating whether it’s design or engineering, everyone really comes together to make a great product.”

- It's not convertible, but we've searched far and wide for the best Ultrabook

Kevin Lee was a former computing reporter at TechRadar. Kevin is now the SEO Updates Editor at IGN based in New York. He handles all of the best of tech buying guides while also dipping his hand in the entertainment and games evergreen content. Kevin has over eight years of experience in the tech and games publications with previous bylines at Polygon, PC World, and more. Outside of work, Kevin is major movie buff of cult and bad films. He also regularly plays flight & space sim and racing games. IRL he's a fan of archery, axe throwing, and board games.