MekaMon – a spider-like quadruped created by UK company Reach Robotics – scampers across the floor and turns to face an enemy robot that's visible on our iPhone screen and threatening our base, which is projected onto a patterned mat on the floor.

It fires a series of energy blasts (our inexperienced firing means we use up most of our ammo) and the rival machine eventually explodes. Our base has been successfully defended. You can also pit two robots against one another, and we were very impressed when had the opportunity to give one a hands-on review.

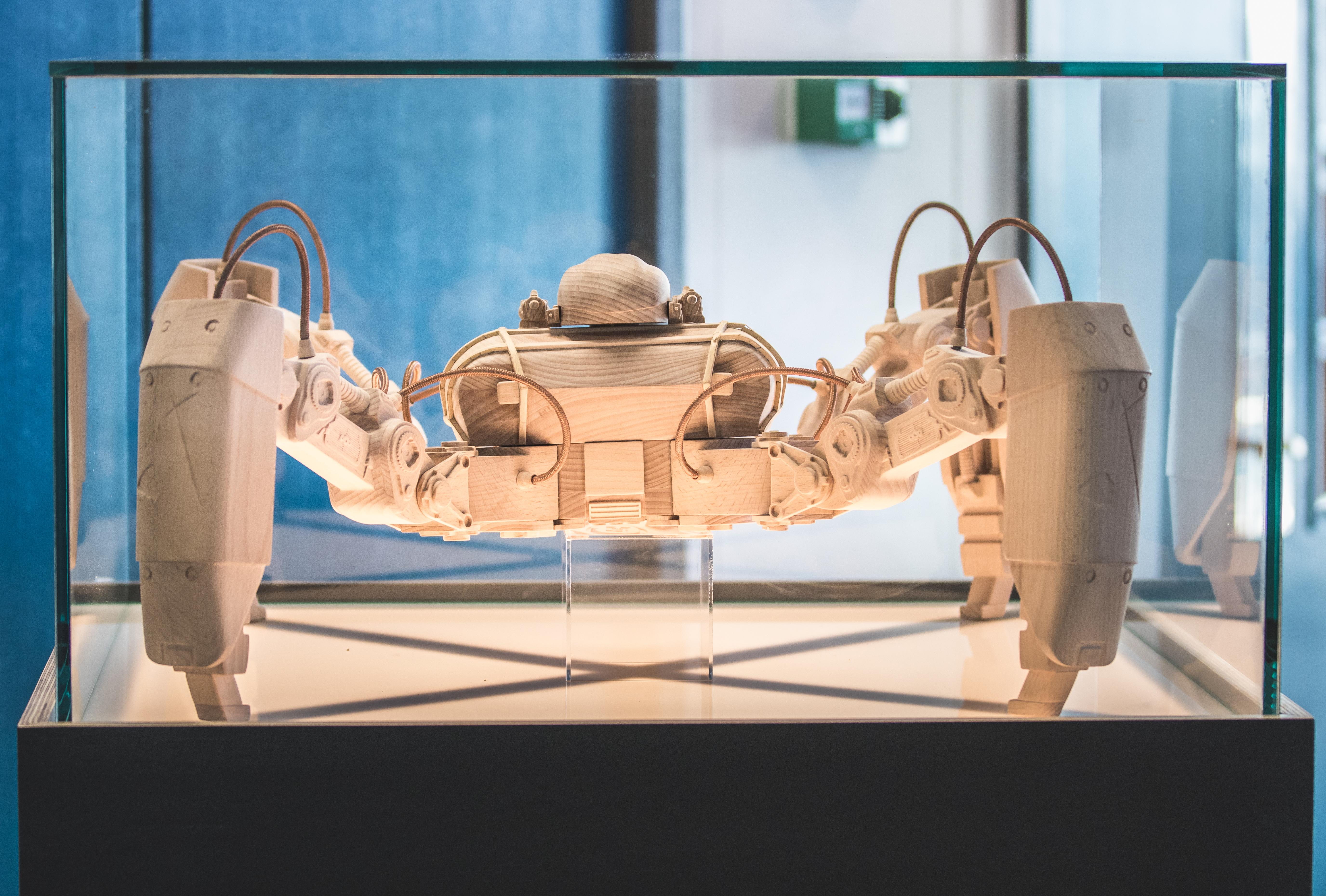

Today, you can see MekaMon in action in any Apple Store in the US or UK, showing off the iPhone’s potential for AR gaming. It’s hard to believe that just four years ago the robot was nothing but a flimsy prototype made by Reach’s CEO Silas Adekunle – and a very persuasive argument.

Bristol is probably the best place, in my mind, if you're going to be in the UK

John Rees, COO, Reach Robotics

“I don’t know how anyone believed him,” says chief technology officer Chris Beck, placing the charmingly wonky model on a coffee table, where one of its legs promptly drops off.

“It was a bit of a leap of faith to go from this to augmented reality,” adds chief operating officer John Rees, clipping it back together.

That early model now sits in the bottom-left corner of Reach’s development wall, which is a hugely impressive illustration of how far the company has come in such a short time, showing all the iterations of MekaMon from those early days to the first commercial models to roll off the production line.

A leap of faith

Reach Robotics was founded in Bristol in south-west England – a city that’s home to Bristol Robotics Laboratory, an internationally renowned centre for research that's shared by the city's two universities.

Get daily insight, inspiration and deals in your inbox

Sign up for breaking news, reviews, opinion, top tech deals, and more.

Adekunle and Rees both studied at the University of the West of England (UWE), along with former head of engineering Arnaud Didey.

“Silas pitched it to those two guys, who who were both working full-time at Airbus,” says Beck. “They said they would help in the evenings with the engineering and so on, but they needed a roboticist. I was doing my PhD at the University of Bristol, which shares the Bristol Robotics Lab with UWE. Silas contacted my PhD partner, who was too busy and said he should speak to me.“

Reach grew slowly for two years, but things picked up when Reach was accepted into the Techstars startup accelerator program, based with Qualcomm in San Diego. Techstars provided the young company with some capital – not much for a hardware company, but enough to allow Rees and Didey to come on full-time. It also allowed the company to hire its first employee – head of games Jonathan Quinn.

“The first week he joined, we told him, ‘Oh yes, we need to go to San Diego by the way. You’re coming with us.’ says Beck. “I had to convince him to leave his partner for six months and come join us.”

The team worked long hours throughout the summer, spending 18 hours per day indoors.

“I was trying to go surfing and I went once, in the end,” Rees recalls. “San Diego’s a cracking spot for that, and I managed to get there once. That’s life as a startup, though.”

Making it real

After six sunless months in San Diego, the five teammates were ready to come home to Bristol. The Robotics Lab was hugely accommodating, always finding more room for the blossoming company, but eventually Reach outgrew the space.

The team didn't have to move far though, and set up a new base at Future Space – a workspace specifically for tech startups, based on the UWE campus.

Future Space is home to three other robotics companies, including Open Bionics, which specializes in low-cost 3D-printed prosthetic hands. Open Bionics also went to Techstars, and returned to Bristol at the same time as Reach.

“Bristol Robotics Lab is regarded as one of the best in Europe, so it’s a good place to be based because we’re trying to grow rapidly,“ Rees says. “It’s not easy finding talent, so Bristol is probably the best place, in my mind, if you’re going to be in the UK.”

”There's not many places where there are so many big engineering companies who cover so many disciplines,” adds Beck.

“Startups are great at talking to each other. Everyone shares – even when you've got similar product areas“

Chris Rees, COO, Reach Robotics

The connections Reach made at Techstars and the robotics lab were also enormously helpful when it came to finding a manufacturer in China.

“Startups great at talking to each other,“ says Chris. “You say, ‘Do you know this or that?’ ‘Have you spoken to this company or had any dealings with this?' or 'Do you know how I can handle the tax over here?' Everyone shares – even when you've got similar product areas.“

“A lot of manufacturers will try to keep their customers separate because they don’t want them to talk to each other,“ adds John. “But ours is good like that. I think we gain a lot from talking to others.“

Expanding Reach

After a great deal of traveling, the team found a manufacturer that’s used to working with startups (and which makes a certain well-known robot vacuum cleaner) and started a strong partnership. However, the company isn't planning to rush into selling in Asia just yet.

“The problem with the Asian markets is they’re very different to the Western markets,“ explains Beck. “We can’t just go there by ourselves and expect our marketing and advertising to work, so we are working with partners in Japan who should help us on that side, and then the same for Singapore and Korea.

“China has never a market to ignore because it is so large, but right now Reach is mostly focused on the US and Europe. We didn’t want to do the whole world at once because that'd be crazy hard. Countries like Canada, Australia and Japan will have similar certifications.“

“They'll have some extra things you need to write on the box, or on the robot somewhere,“ Rees adds. “You have to find space for it. But a lot of the testing’s the same.“

“A lot of hardware companies make the mistake of trying to go global right from the outset“

John Rees, COO, Reach Robotics

“They just basically set fire to our robot,“ Beck laughs. “Smash it up. We provide them with 20 and they get absolutely destroyed.

“The very first time we hand-made the 20, and it was like ‘It took us a week to make these on the production line!’ And now you’re kinda like ‘Yeah, destroy ‘em!’ John still cares too much about them.“

“They’re my babies,“ Rees admits. “But yeah, a lot of hardware companies make the mistake actually of trying to go global right from the outset. There there are quite a lot of things to consider.“

MekaMon's next steps

Right now, Reach is focused on expanding its UK team, and updating and improving the robot scampering across the office floor.

“We're a connected play experience,“ Beck says. “For us, also that means you don’t buy a toy that dies in a week and doesn’t upgrade.“ The whole point of us is, you buy a robot for entertainment and we keep updating it and growing it.“

The MekaMon app receives regular updates, and everything about the robot itself is modular – legs can be removed and reattached at will, and customers will soon be able to upgrade the hardware as well as the software, adding new features and changing the gameplay.

“That's how we're trying to keep it fresh for the customer,“ says John. “It's a $300 product so we don't want to them to play with it for a week and then never come back to it.“

Reach is also recruiting for 15 new roles, and has a whole floor to house them. Although it's based in the UK, the team is keen to hear from enthusiastic people anywhere in the world.

“Number one on our list is the people and culture,“ says John. “We have a strong emphasis on the culture of fun, and trying to make sure that although we're working hard, we're also enjoying that time here.

“We like to see ourselves as pushing people, products, profit in that order. That’s the key for us: if we look after the people the rest will come.“

Cat is TechRadar's Homes Editor specializing in kitchen appliances and smart home technology. She's been a tech journalist for 15 years, having worked on print magazines including PC Plus and PC Format, and is a Speciality Coffee Association (SCA) certified barista. Whether you want to invest in some smart lights or pick up a new espresso machine, she's the right person to help.