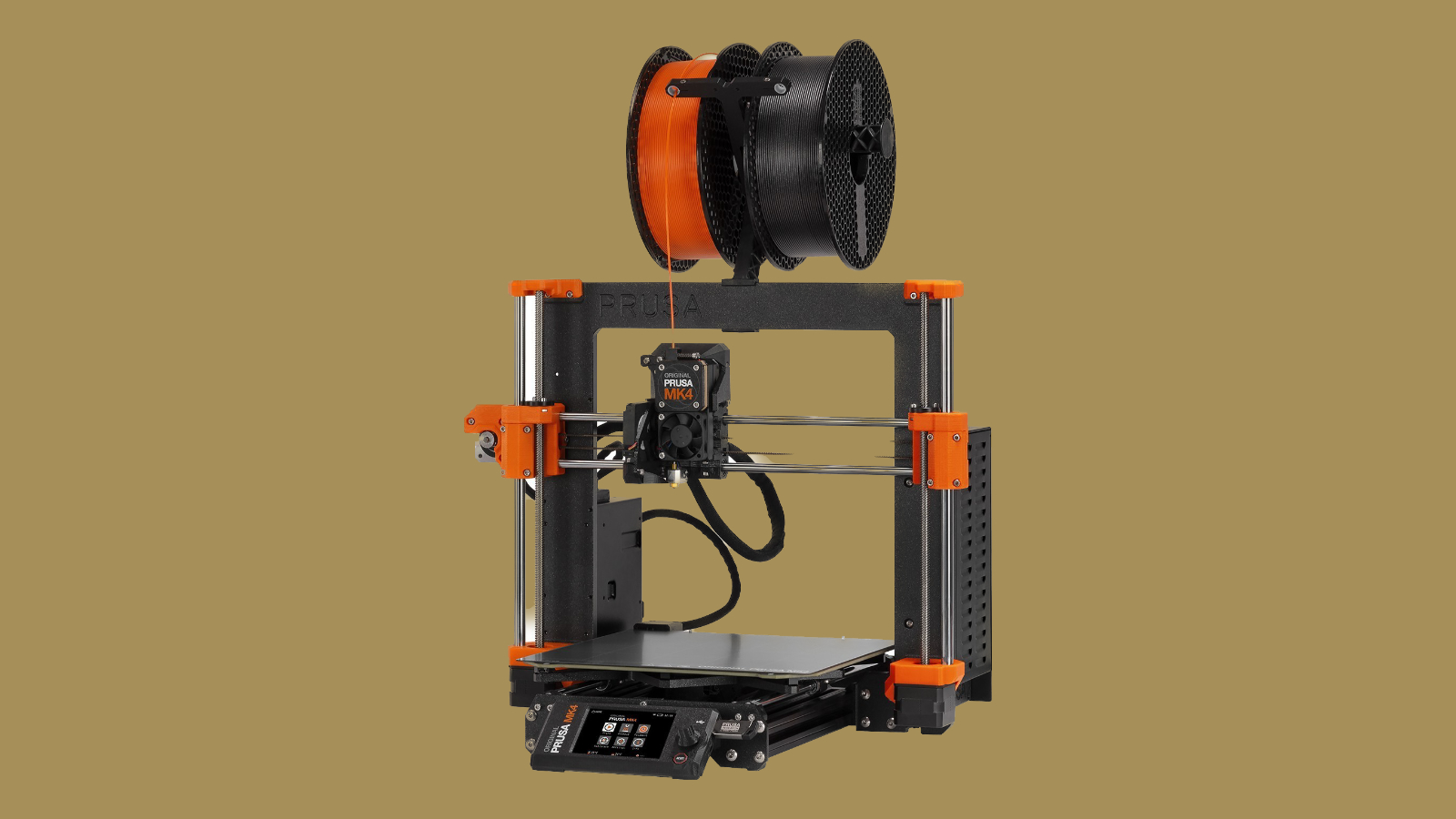

The Prusa MK4 might be the fastest and most efficient 3D printer out there

Meet the Original Prusa MK4, the high-speed 3D printer delivering ease and open-source principles

Prusa Research has launched its much-anticipated Original Prusa MK4 3D printer, which promises to deliver high-speed printing with ease.

The company says the MK4 is more than just an upgraded version of the popular MK3 (despite the similar looks) with 90% of the machine being all-new and offering a host of features and improvements.

Prusa says this makes it look likely to be one of the fastest and most reliable 3D printers on the market today.

Original Prusa MK4

In a call with Josef Průša, I asked why the company had decided to stick with the iconic design of the Original PRUSA's that had come before.

The answer was straightforward - the Original Prusa customer base is loyal, and to cut off the development for those existing users now is not an option, especially when the performance of the MK4 can more than compete with the latest Core XY machines when it comes to speed and speed reliability. A clear upgrade path must be part of the PRUSA model, as does ensure that the open-source community is maintained.

While the new MK4 machine may look familiar, the upgrades enhance almost every aspect of the build and technology. Most noticeably, the metal frame of the MK3 that was machined from sheet metal is replaced by an all-new aluminum composite injection molded frame, which provides greater rigidity.

Build Volume: 250 x 210 x 220 mm | 9.84 x 8.3 x 8.6 in

Filament diameter: > 1.75 mm

Layer height: 0.05-0.30 mm

Mainboard: Custom 32-bit xBuddy electronics with STM32

Stepper Drivers: Trinamic 2130

Stepper motors: Precise 0.9° X, Y stepper motors (prevents VFA)

Extruder: Nextruder, Direct Drive, E3D V6 compatible (with adapter)

Drive system: Nextruder Planetary Gear System, 10:1 gearbox ratio

Nozzle diameter: 0.4mm (default) / other nozzle diameters supported

Max nozzle temperature: 300 °C / 572 °F

Max heatbed temperature: 120 °C / 248 °F

LCD screen: 3.5″ graphic 65k colour screen

Connectivity: LAN, Optional ESP wifi module (delivered with the printer)

Print medium: USB drive / LAN / internet via Prusa Connect

Advanced sensors: Filament sensor, Loadcell sensor, Power panic, 4 high-precision thermistors (genuine Semitec) + fan motors RPM monitoring

Print surface: Magnetic heatbed with removable PEI spring steel sheets

Bed calibration: Automatic, Mesh Bed Leveling (only on print area)

Supported materials: PLA, PETG, ABS, ASA, Flex, HIPS, PA, PVA, PC, PP, CPE, PVB, NGEN, composites, and more

Printer dimensions (without spool): 7 kg, 500×550×400 mm; 19.6×21.6×15.7 in (X×Y×Z)

Power consumption PLA settings: 80W / ABS settings: 120W

Among the other most notable upgrades is the new high-speed extruder, which allows for faster printing speeds while maintaining high-quality prints. This extruder is compatible with many filaments, including PLA, ABS, PETG, etc.

Are you a pro? Subscribe to our newsletter

Sign up to the TechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

This new print head has been developed by PRUSA Research and based on the Nextruder that we first saw on the XL, and now the smaller version that features on this new printer again features quick swap nozzles.

For many, the most groundbreaking feature is the new fully automatic first layer calibration, thanks to a Load Cell sensor. This means that even if you swap out the default nozzle for any standard E3D V6 (with an adapter), the probe will still automatically set the first layer height accurately. This means that the need for fine Z-axis adjustment should be history.

Another feature that will appeal to many users is the upgraded connection options with ethernet and wifi. This means there will be no more toing and froing from the machine to load or update files through production iterations.

A new print bed features an improved surface texture, providing better adhesion and eliminating the need for adhesives or other surface treatments. Regarding materials as standard, there's wide compatibility, and specialist nozzles can be fitted with the quick swap system. In addition, the MK4 has a new filament sensor that detects when the filament runs out and automatically pauses the print, allowing users to easily swap out filaments without starting the print job all over again.

Prusa Research has also enhanced the printer's firmware to the next generation and fully used the 32-XBuddy control board, which now includes advanced thermal runaway protection and automatic skew axis calibration. This ensures the printer operates safely and efficiently, requiring minimal manual intervention.

But perhaps the most significant aspect of the MK4 is its commitment to open-source principles. Prusa Research has a strong heritage in the open-source community and is dedicated to keeping its printers and software open and accessible to everyone.

Open source backing

In a recent blog post, Prusa discussed the importance of open source in the 3D printing world and expressed his concerns about the current state of open source development.

"We stand by our roots in open-source and will continue to do so," he wrote. "Our desktop 3D printers will always be open source. We intend to continue publishing plastic parts and firmware source codes."

Prusa Research's commitment to open source is evident in the MK4, which has models of all plastic parts and firmware sources available for download. While the electronics plans have not been released yet, the company has indicated that it plans to release them under a new license that addresses some issues facing open-source development.

Overall, the Original Prusa MK4 is an impressive 3D printer that builds on the success of its predecessor while introducing a host of new features and improvements. With its commitment to open-source principles, it's a printer that will appeal to makers, hobbyists, and professionals alike.

- Also check out our list of the best all-in-one printers out there