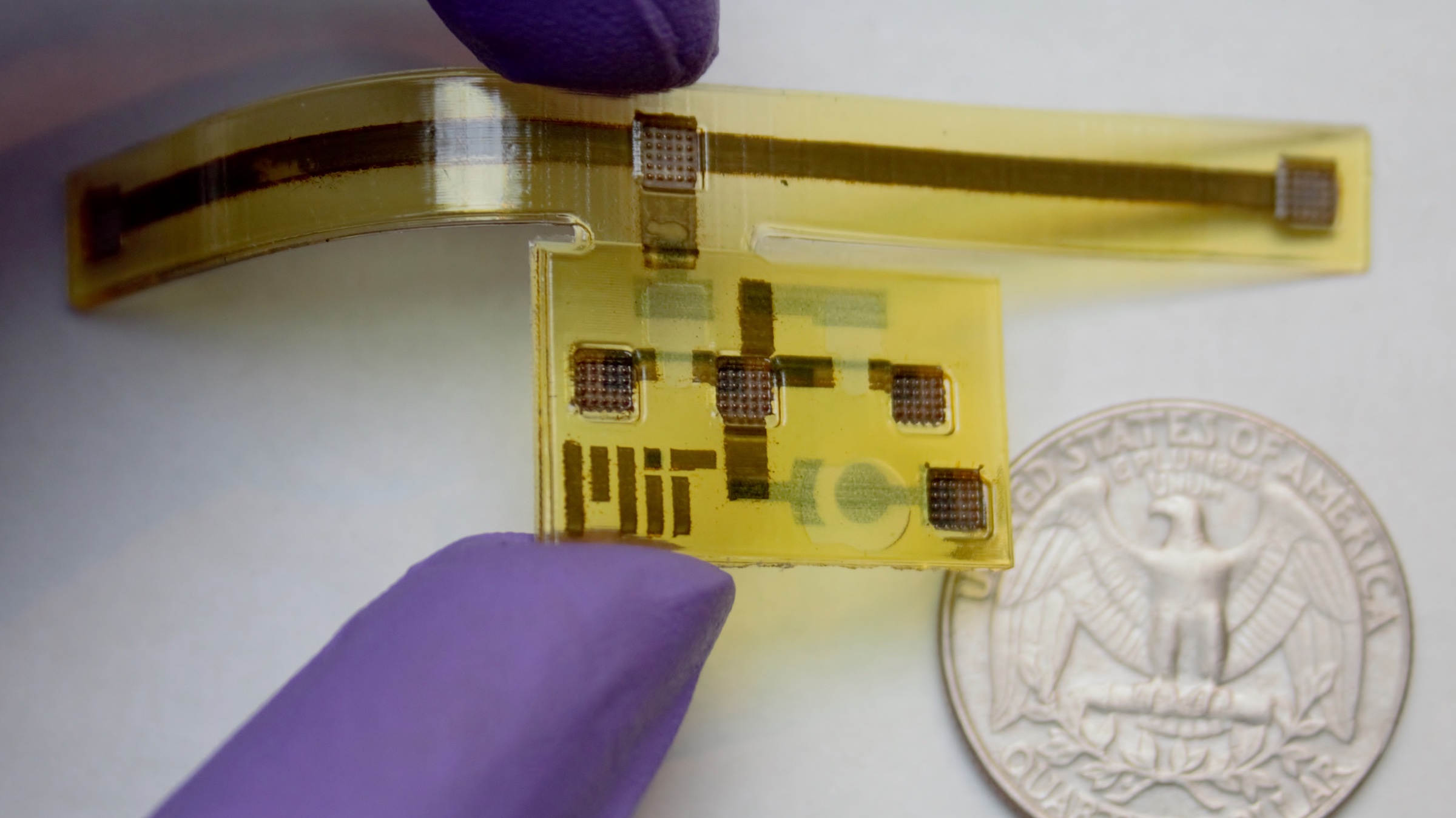

This 3D-printed device could be used in robot skin

Changing color based on pressure

We've written quite a bit about artificial skin in the last few years. It's a fast-moving field -- a lot of research is going into developing thin electronic systems packed with sensors that are not only flexible but also cheap to manufacture in bulk.

The idea is that such systems could be used to allow robots to experience the world around them in a similar way to humans - passively sensing pressure, temperature and more through their skin. It has applications beyond robotics too - bridges could feel when they're failing, for example, and alert someone.

The latest research comes out of MIT's Computer Science and Artificial Intelligence Laboratory. Researchers there have 3D-printed a device that can respond to mechanical stresses (like being poked) by changing the color of a spot on its surface.

Initial demonstration

It was inspired by the golden tortoise beetle, a species native to the Americas. The beetle's skin normally appears golden, but turns red-orange when poked.

“In nature, networks of sensors and interconnects are called sensorimotor pathways,” said Subramanian Sundaram, who led the project.

“We were trying to see whether we could replicate sensorimotor pathways inside a 3-D-printed object. So we considered the simplest organism we could find.”

The resulting T-shaped device is made of elastic plastic with a strip of silver mounted on it, and a more rigid section of plastic with two printed transistors and a "pixel" - a semiconducting polymer which changes colour when the silver strip is stretched. It's powered by a regular 1.5V battery.

Get daily insight, inspiration and deals in your inbox

Sign up for breaking news, reviews, opinion, top tech deals, and more.

It was printed on a custom 3D-printer developed by the researchers, using two different print heads (for hot and cool substances) and ultraviolet light-emitting diodes to harden the printed substances.

Right now, it can operate for about two months, but the researchers say that by replacing some components it could be made more durable.

"That’s something we would work on later," said Sundaram. "This is an initial demonstration."

The team published their work in the journal Advanced Materials Technologies.