Carbon nanotubes unzip future touchphones

New process will mean lighter, cheaper transparent displays

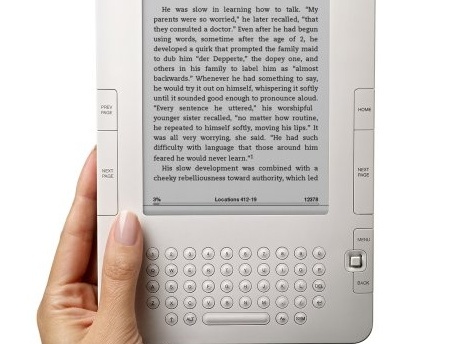

A new invention at Rice University in Texas is paving the way for a new generation of ultra-light, tough and cheap touchscreen displays, HD televisions and ebook readers.

Professor James Tour has developed a room-temperature chemical process that splits, or unzips, carbon nanotubes to make flat nanoribbons, making it possible to produce the ultrathin ribbons in bulk quantities.

Carbon nanotubes are exciting because they are light, thin and conductive - and yet are 200 times stronger than steel.

Paintable polymer nanotubes

The unzipping action turns the tubes (thousands of times thinner than a human hair) into flat, straight-edged, water-soluble ribbons of graphene. When produced in bulk, these microscopic sheets can be 'painted' onto a surface or combined with a polymer to let it conduct electricity.

Single-walled carbon nanotubes convert to sheets at room temperature and are good for small electronic devices because the width of the unzipped sheet is highly controllable.

But the multiwalled nanotubes are much cheaper starting materials, and the resulting nanoribbons would be useful in a host of applications.

Get daily insight, inspiration and deals in your inbox

Sign up for breaking news, reviews, opinion, top tech deals, and more.

Swift commercialisation

"If a company wants to produce these, they could probably start selling small quantities within six months," says Professor Tour. "To scale it up and sell ton quantities, it might take a couple of years. That's just a matter of having the right reactors. But the chemistry is all there. It's very simple."

Tour is excited by the possibility that conductive nanoribbons could replace indium tin oxide (ITO), a material commonly used in flat-panel displays, touch panels, electronic ink and solar cells. "ITO is very expensive, so lots of people are looking for substitutes that will give them transparency with conductivity," he says.

Tour envisions nanoribbon-coated paper that could become a flexible electronic display, and he's already experimenting with nanoribbon-infused ink for ink-jet printers. "We're printing transistors and RFID tags, printing electronics with these inks," he said.