TechRadar Verdict

The Anycubic Kobra 2 Pro builds on the superb foundation set by the Kobra 2 Neo and combines speed with user-friendly features. The printers setup is straightforward enough, even for beginners, further enhanced by an intuitive interface that simplifies calibration and control.

Pros

- +

Exceptional speed

- +

Advanced flow control

- +

Intelligent leveling

Cons

- -

No video monitoring at present

- -

External app dependence

Why you can trust TechRadar

The Anycubic Kobra 2 Pro presents itself as a compelling entry-level 3D printer, showcasing several significant upgrades over its predecessor, which we tested out in our Kobra 2 3D printer review.

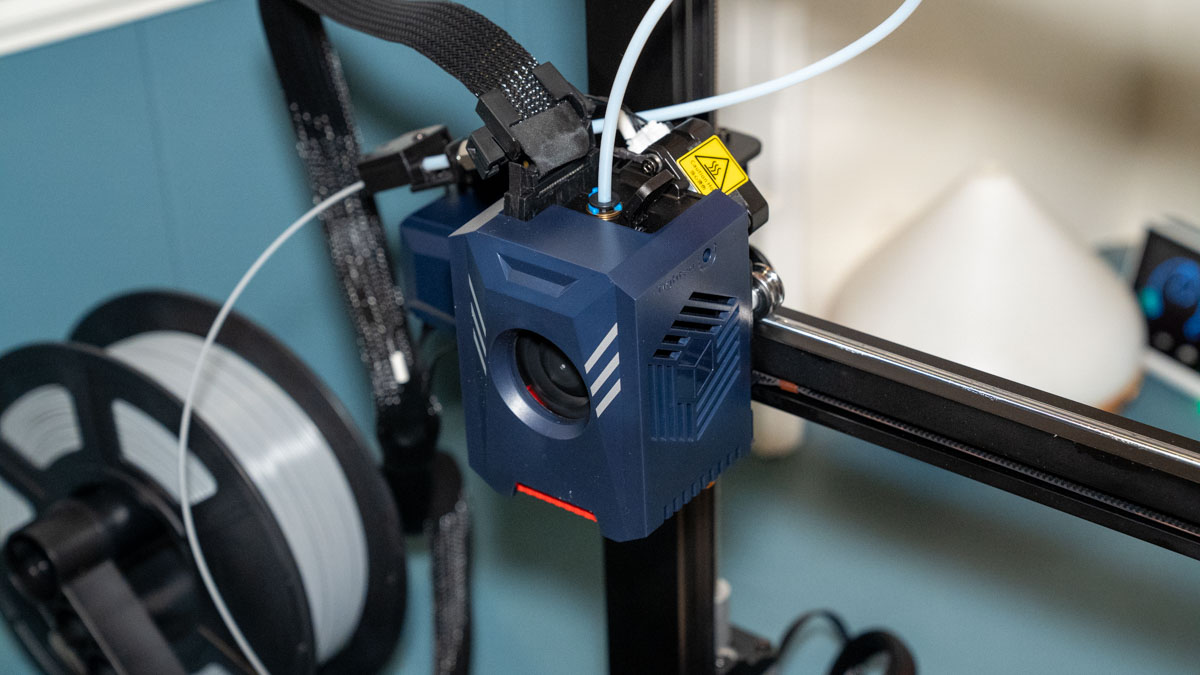

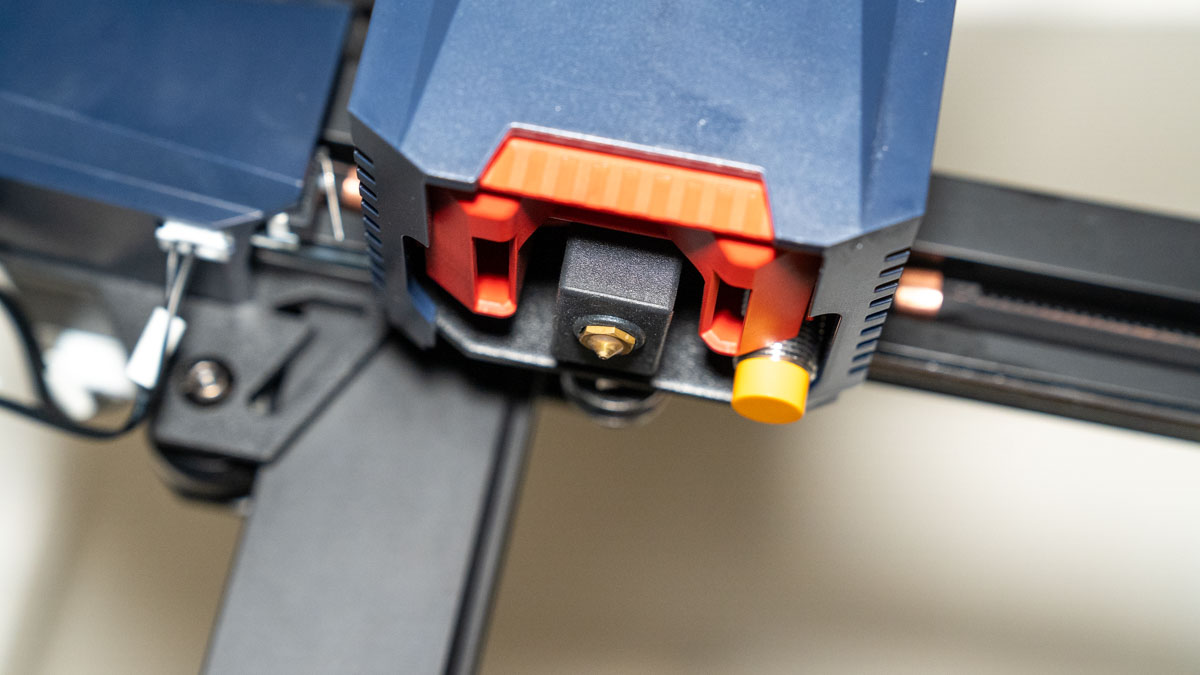

The most notable enhancement is its accelerated printing speed, reaching up to a swift 500mm/s. Additionally, it boasts increased processing power, courtesy of an advanced Cortex-A7 processor, which contributes to its overall improved performance. Visually, the printer features a new tool head with a refined direct extruder and structure designed for producing smoother prints.

However, as with any 'Pro' version, these advancements do come with a higher price tag. We wanted to see whether the enhanced features of the Kobra 2 Pro are worth the extra investment Is it a sensible upgrade or is the more economical Kobra 2 the best 3D printer for enthusiasts?

Anycubic Kobra 2 Pro: Design

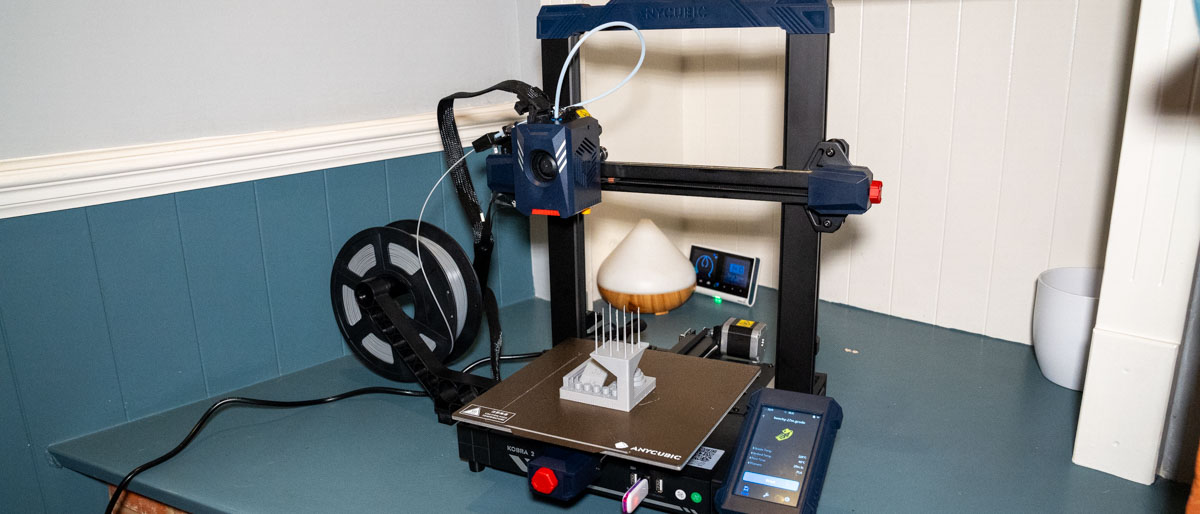

The Anycubic Kobra 2 Pro makes a strong impression straight out of the box. While bearing a resemblance to the standard Kobra 2 Neo in style, it quickly becomes clear that this model is a substantial upgrade. Key improvements include dual threaded screws, a more robust tool head, and a selection of USB slots on the front for file downloads or feature extensions.

As with the entire Kobra 2 range, this printer adopts an open-frame Cartesian style. This design choice not only makes it easy to use but also educational, with all its workings on display—an excellent feature for beginners eager to learn about the mechanics of 3D printing.

As with most 3D printers at present the main assembly is done for you and the rest is relatively straightforward, and thankfully the printed manual provided by Anycubic is excellent. The construction process should take about 5-10 minutes and shouldn't cause any real challenges. However, if you are new to 3D printing, having an extra set of hands for the initial assembly can be helpful.

Once constructed and powered on, the printer handles calibration, and once done, the loading of the filament into the system is straightforward. Within 30 minutes, you should be ready to start your first print. With this version of the Kobra 2 printer, Anycubic has developed their own AnycubicSlicer, which is well-suited to beginners and easy to navigate. If you do like a little more control, then setting this printer up for use with CURA is realitively easy.

The design and software of the Kobra 2 Pro combine well, but what stands out with this model is the added functionality of controlling the printer via the Anycubic App.

Anycubic Kobra 2 Pro: Features

The 3D printer standout feature has to be the impressive 10X increase in printing speed from it's predecessor. This leap in performance is powered by a high-power processor and an optimised direct extruder, all helping to ensure a fast and precise filament feed, quick melting and cooling, and enabling smooth motion and significantly reducing layer lines.

When it comes to the print volume, the Kobra 2 Pro sits in the middle ground between the Kobra 2 Neo and the Kobra 2 Plus. While the technological leap from the Neo to the Pro is considerable, the Pro and Plus are nearly identical in terms of technology, differing mainly in size. The same applies to the larger MAX model. The Kobra 2 Pro offers a print area of 220x220x250mm, fitting comfortably within the range.

Print Technology: Fused Deposition Modeling (FDM)

Build Area: 250 x 220 x 220 mm

Minimum Layer Resolution: 0.08

Maximum Layer Resolution: 0.28

Dimensions: 486 x 435 x 463 mm (HWD)

Weight: 8.4 kg

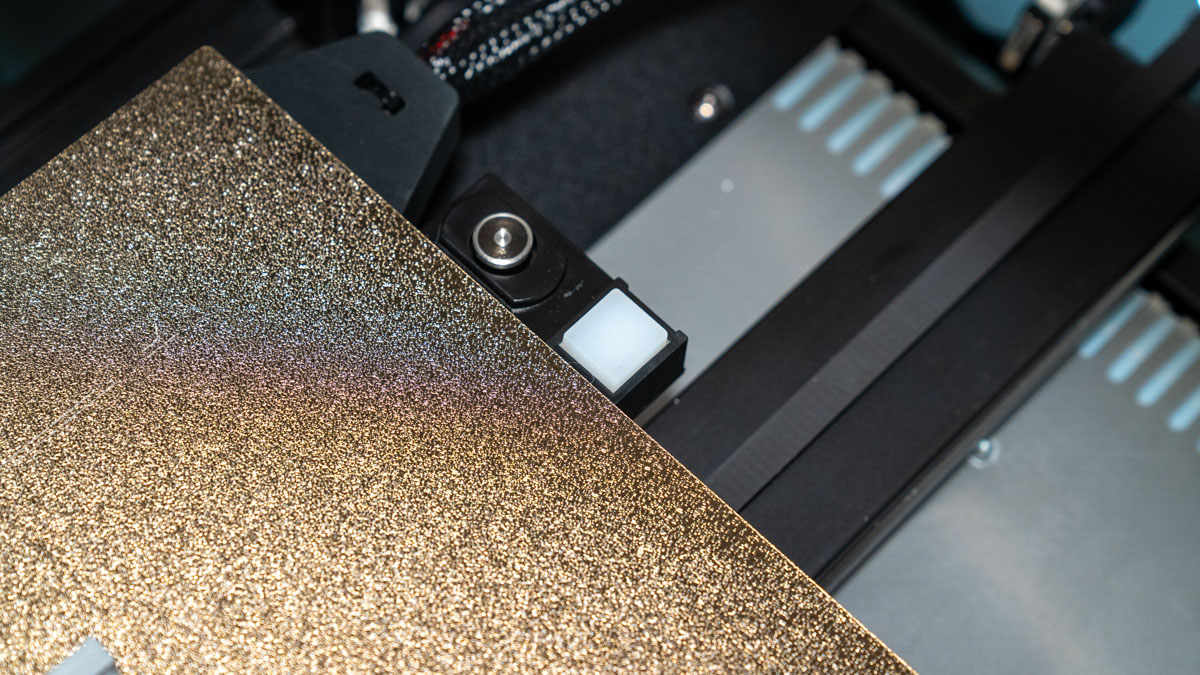

Bed: Heated Textured Flexible Removable Platform (PEI Magnetic Spring Steel)

Print Surface: Textured PEI Magnetic Spring Steel

Software: Compatible with major slicing software; specifics not provided (Cura, PrusaSlicer compatibility expected)

Materials: PLA, ABS, PETG, TPU, etc.

Print Speed: 500mm/s (Max.), 300mm/s (Typical)

While auto bed levelling is becoming a standard feature, the Kobra 2 Pro's advanced LeviQ 2.0 automatic levelling system takes things up a notch with 25 points across the print platform checked to ensure a clean first layer print. The system works by utilising an inductive sensor, and then it intelligently compensates for any surface irregularities. Additionally, the machine incorporates a dual-shaft core with SG15 bearings to enhance accuracy, opting for a double-threaded rod instead of the double-motor double Z-axis found in the Plus and Max models.

The Kobra 2 Pro is equipped with a filament run-out sensor, a feature that is now pretty common and really an absolute essential. This sensor plays a crucial role in ensuring continuous print. It detects the end of the filament if it runs out unexpectedly, with the result that it will automatically pause the print.

At the heart of the 3D printer's user interface is its responsive touch screen, offering a seamless and intuitive way to interact with the printer. This 4.3-inch LCD enables easy and fast navigation through all of the machine's menus, allowing you to quickly access and modify print settings, monitor ongoing jobs, and control the printer.

The printer's high-power processor is another highlight, offering plenty of computing power for faster processing and smoother motor movements, all helping towards that improved printing speed over previous models.

While the Kobra 2 Pro does not include built-in video monitoring, it is designed to work with the forthcoming Anycubic app for remote networking and control. The inclusion of 3 USB ports on the front facilitates direct file loading and will support camera connectivity for enhanced monitoring capabilities once available.

Anycubic Kobra 2 Pro: Performance

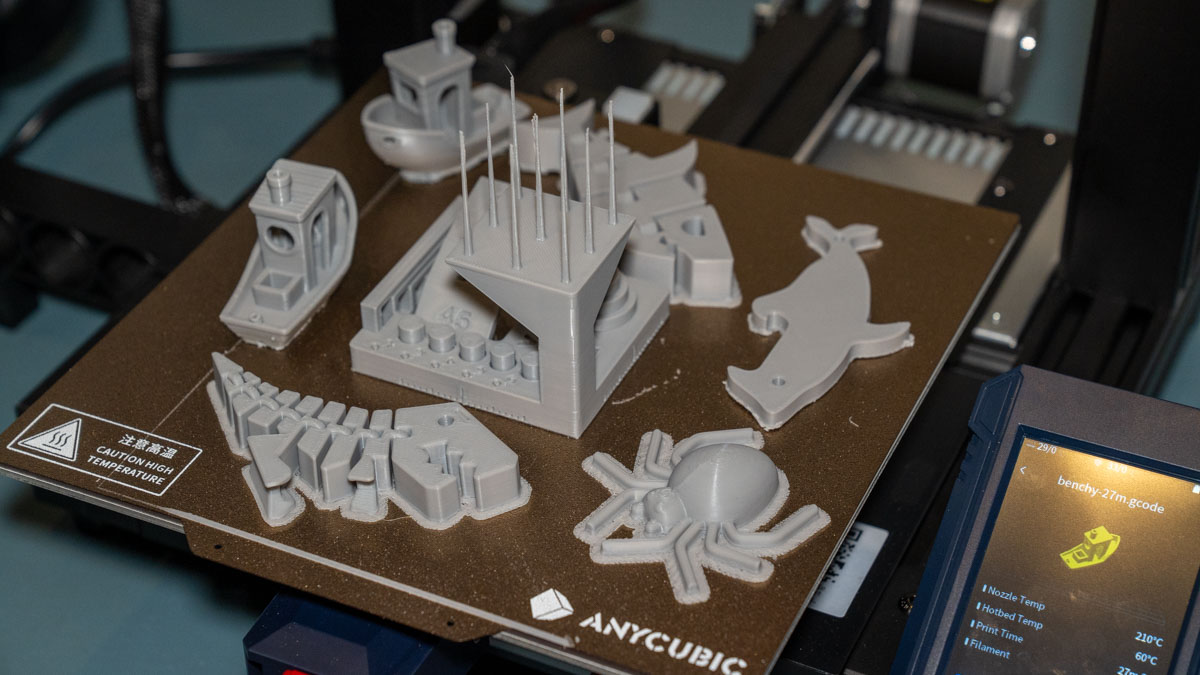

Throughout our testing phase, the Kobra 2 Pro showcased its versatility and quality by successfully printing a variety of models from Anycubic, downloaded sources, and user-created designs. Initially, some minor dimensional accuracy issues were encountered, but these were swiftly rectified by adjusting the belt tensions, as clearly guided by the manual.

Post-calibration, the Kobra 2 Pro demonstrated a notable improvement in print quality, surpassing the performance of the Kobra 2 Neo. Its dimensional accuracy, with an average error margin of just 0.128mm, marks it as an ideal tool for model makers and product designers who rely on precise dimensions in their work. The printer's exceptional fine flow control, scoring perfectly, signifies its adeptness at managing intricate details and producing smooth surfaces, making it a great fit for crafting and decorative projects.

The printer's proficiency in bridging, evident in its ability to handle complex geometries and overhangs, extends its utility to architectural models and functional parts in product design. Its compatibility with various materials, achieving minimal stringing and excellent layer adhesion, broadens its appeal to an array of users, including hobbyists and crafters. However, its open design may limit its suitability in educational settings and some office environments, where enclosed printers are often preferred for safety and noise considerations.

Overall, the Kobra 2 Pro emerges as a strong, reliable, and versatile 3D printer. It excels in balancing speed, quality, and user-friendliness, making it an attractive option for hobbyists, crafters, and product designers, as well as for more intricate work in model-making and crafting.

Anycubic Kobra 2 Pro: Print quality

Dimensional accuracy - score of 4

Target 25 = X: 24.83mm / 0.17mm Error | Y: 24.97mm / 0.03mm Error

Target 20 = X: 19.94mm / 0.06mm Error | Y: 19.78mm / 0.22mm Error

Target 15 = X: 14.92mm / 0.08mm Error | Y: 14.76mm / 0.24mm Error

Target 10 = X: 9.82mm / 0.18mm Error | Y: 9.77mm / 0.23mm Error

Target 5 = X: 5.05mm / 0.05mm Error | Y: 4.98mm / 0.02mm Error

X Error Average = 0.108

Y Error Average = 0.148

X&Y Error Average = 0.128

Fine Flow Control - score of 5

Fine Negative Features - score of 3

Overhangs - score of 3

Bridging - score of 5

XY resonance - score of 2.5

Z-axis alignment - score of 2.5

Adding up the totals gives a final score of 25 out of 30.

Anycubic Kobra 2 Pro: Verdict

The Anycubic Kobra 2 Pro stands out as an exceptional 3D printer, offering impressive speed and consistent output at a competitive price point. Its robust build, complemented by features like a dual-gear extruder, high-power hotend, and App connectivity, make it highly adaptable for a variety of printing tasks. The LeviQ 2.0 auto-leveling system enhances its ease of use, making it a viable option for both novices and seasoned users.

The printer excels in producing smooth, detailed prints, especially when using high-quality PLA filament. Thanks to its automated calibration and large touchscreen, the Kobra 2 Pro is incredibly user-friendly.

While testing the Kobra 2 Pro the machines versatility and print quality stood out. Initially, we did have a fewminor dimensional accuracy issues, but these were easily fixed by adjusting the belt tensions, and the what could be causing the issue and how to fix it were all clearly shown in the manual which was hand.

Post-calibration, the Kobra 2 Pro demonstrated a notable improvement in print quality, far surpassing the performance of the quality of prints that we had seen from the Kobra 2 Neo. The machine's dimensional accuracy, with an average error margin of just 0.128 mm, highlights that this is a machine that would be an ideal tool for model makers and product designers who rely on precise dimensions. The printer's fine flow control, scoring perfectly, highlights how it can easily manage intricate details and produce smooth surfaces when required.

- Best 3D modeling software: Tested, reviewed, rated