TechRadar Verdict

Far from being a jack of all trades, the H2D matches—and in some cases exceeds—the quality of dedication machines, the 3D print quality being a case in point. The fact that it features excellent laser engraving and cutting all add to the appeal. Tool swaps are straightforward, and despite a few quirks, they come together to add great value.

Pros

- +

Dual nozzle 3D print head

- +

Up to 40 watts laser

- +

Decent cutting

Cons

- -

Laser area is small

- -

Workflow issues with advanced materials

- -

Purges filament when using more than two

Why you can trust TechRadar

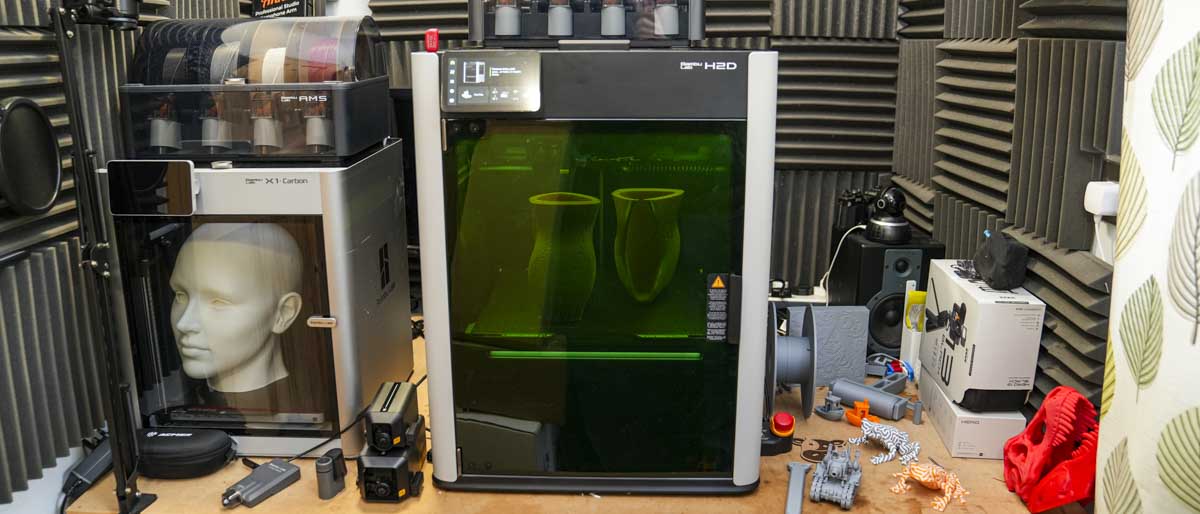

The Bambu Lab H2D is one of 2025's most hotly anticipated 3D printers, rumoured to be a large-format, multitool from the most exciting and disruptive manufacturer in the market today.

Over the last month, I've followed the speculation closely, reading the rumours while having two H2Ds sat in the workshop, one standard and the other the Laser Edition that I'll be covering in this review.

From the moment the printers arrived, both were quickly unpacked, set up and fired into action. Each features a dual nozzle setup, a new AMS 2 system and a larger build area than the company's previous machines. Visually, they look pretty similar, with the green glass of the Laser Edition being the only real visual difference on the exterior. Inside the box of the laser edition, however, you get the 10W laser and cutter/plotter tool head, which are all upgrade options if you go for the straight H2D.

When it comes to tool head swapping, this is fast and intuitive, with a quick release mechanism holding them in position once slipped into place and a single cable connecting to the machine.

Software support is a little convoluted at present with the 3D printer aspect of the machine using Bambu Studio, while the laser engraver, digital cutter, and plotter rely on a new application: Bambu Suite. This might not be quite as joined up as having an all-in-one application like SnapMaker Luban, but each application works extremely well.

Crucially, when it comes to swapping between heads, unlike other systems where heads are removed entirely, the H2D keeps the dual nozzle tool head in place, and the additional tools mount directly to the front—simplifying changeovers. I found this was actually made to simplify tool head changes.

Managing filament takes a little getting used to. The AMS connects to the left-hand nozzle, while the right feeds via an external spool for specialist materials like TPU. Print quality, whether single or multifilament, is excellent, and the dual nozzle system gives a considerable speed edge over the X1C Carbon.

The accuracy of the H2D is a major feature and one of the reasons the new machine costs more than the smaller X1C Carbon, but that extra investment brings business-level precision, especially when paired with optional hardware like the vision-calibrated plate.

Beyond printing, the laser module also performs well, offering sharp, consistent engraving. The bed size, however, is compact, and that size is a little restrictive, but performance is on par with dedicated machines. The same applies to digital cutting and plotting, which share a tool head and support pens or blades—offering familiar functionality but with greater precision and speed.

Across all three functions—3D printing, laser engraving, and digital cutting—the H2D is well-engineered and clearly aimed at professionals and serious makers. TPU can still be a bit fiddly, as ever, but overall usability has improved over earlier systems.

What's most exciting is how the machine's strengths combine. You might start with a 3D print, add a TPU midsole, cut fabric uppers, and finish with laser detailing—all in one workspace. There are still a few workflow quirks, and it takes some planning, but once everything clicks, the H2D Laser Edition proves itself one of the most capable and complete maker machines currently available, and a clear contender for both our best 3D printer and best laser engraver guides.

Bambu Lab H2D: Design

In this review, I'm taking a look at the H2D Laser Edition; I have both, but putting out two reviews of an almost identical machine, even for me, is a bit much, at least on the same day. An individualised review of the H2D will inevitably follow.

The laser edition is one of two new H2D machines launched by Bambu Lab. The standard H2D features the dual nozzle tool head and AMS 2 multifilament box and has clear windows, while the Laser Edition adds extras, including the laser, digital cutter and plotter head alongside that same dual-nozzle extruder and a host of build plates.

The dual nozzle tool head is a smart approach to design. While similar-looking heads have been seen from brands like Ultimaker, Snapmaker, and previously CEL-UK with the RoboxDual, most manufacturers lean towards IDEX or full tool-changer systems such as the Snapmaker J1 or the Raise3D E2. Bambu Lab's route keeps the tool head compact with a filament management system that's been designed to be as seamless as possible.

As materials like PLA Support, CF and TPU become more common in advanced 3D printing, containment and moisture control have become critical. The big upgrade here is that the AMS 2 not only manages and organises filaments but maintains their moisture level for optimal output. Specialist filaments like TPU, however, are not supported by the new AMS and can be fed into the system separately via a separate dry box.

In daily use, the H2D performs much like the X1C Carbon, but the updated AMS brings added functionality, including the ability to act as a dry box. The system is modular, too—you can expand as needed as with the original system, and there is some cross compatibility - essentially, the two look identical, and you still can't stack the new design.

With two nozzles, additional materials can be loaded without unloading or retracting, making multi-material prints much faster. AI-enhanced features further improve reliability, catching errors like spaghetti printing, nozzle blocks, or platform detachment - although it can all be a little over-sensitive.

For advanced users, this is one of the first machines to offer a managed heated chamber, complete with temperature sensors, vents, and circulation fans. What's slightly different here from other systems that I've seen is that it keeps the environment stable for different materials; during printing, the top vent pops open and closed, and early on, I found that putting prints onto the vent was not advised.

To enhance print accuracy, Bambu Lab has also developed the Vision Encoder Plate—a specialised platform that helps calibrate motion and alignment; in this test, calibrating with this matt made a real difference, and while the overall print scores remained much the same, there were some interesting visual changes to the test prints. However, it's worth noting that this plate is not necessary for every user; for those working in production or product design, it's a valuable addition at this price point.

The dual nozzle setup is already a clear evolution over the X1C Carbon, and with the AMS Pro backing it, the H2D takes things further. Adding the laser head to the front of the printer transforms it into a high-speed laser cutter and engraver. The machine supports both 10W and 40W modules—both accurate and fast, though I found early tests required slightly higher power than the default settings suggested.

The digital cutter and plotter are the least familiar territory for me, though I have some experience. This head simply locks onto the front of the dual nozzle assembly, and once a cutter or pen is inserted and programmed via Bambu Suite, it's ready to go.

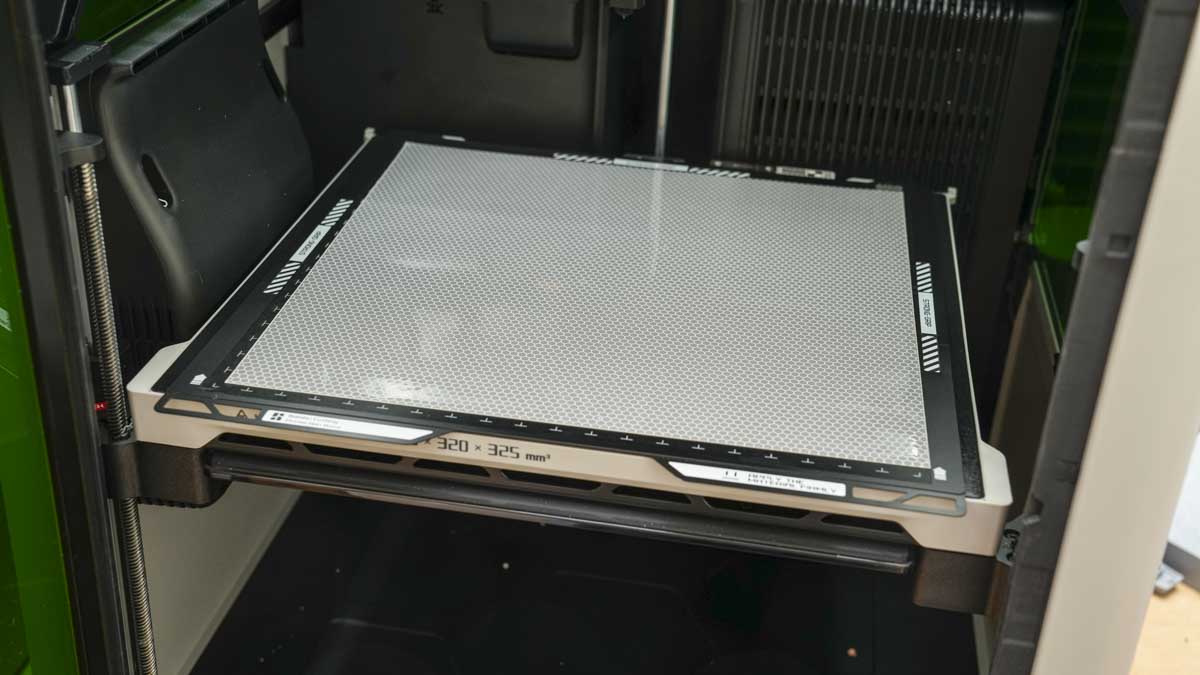

Tool changes between each of the heads take only a few minutes, and that is a manual rather than automatic process; this is no PRUSA XL. To make a tool head change, just switch off the machine, slide in and clamp the tool head module, swap the platform, and it's ready to go. One of the features that I liked is that the platforms are magnetised—no levers or screws, just like standard 3D print platforms—making the switch between each clean and easy. Compared to other multi-feature machines, it's extremely user-friendly.

Bambu Lab H2D: Features

Print Technology: FFF

Build Area: 350x320x325mm

Minimum Layer Resolution: n/a

Maximum Layer Resolution: n/a

Dimensions: 492x514x626 mm

Weight: 31kg

Bed: Heated / Laser / Cutting

Print Surface: Flexible Steel Plate

Software: Bambu Studio / Bambu Suite

Materials: Multiple

Print Speed: 1000mm/s

The first thing to know about the H2D is that it's far more than just a 3D printer. It's also a capable laser engraver, cutter, and digital cutter/plotter, essentially offering a multifunctional manufacturing platform—combining multiple fabrication tools into one unit. Sounds good, and what's more, it takes up far less space on a work surface than three or four individual machines.

Of course, this isn't the first machine to offer modular tool head solutions, with the superb but huge Snapmaker Artisan being the most obvious example; even some of the Creality printers offer a tool head swap so you can attach a laser. However, while Snapmaker chose CNC as its third tool, Bambu opted for a less messy, more accessible option in digital cutting and plotting; this will definitely please the crafters out there. The company has also focused heavily on refining its ecosystem, integrating airflow management, laser safety, flame detection, and a vision-based alignment system—all designed to keep volatile tool heads safe and user-friendly and enable multiple tools to be used on the same project.

The main feature of the machine here remains the dual nozzle tool head that offers a large 350 x 320 x 325 mm build area and a 350°C high-flow hot end. To beat its own X1 Carbon—a standout machine—Bambu added a vision-assisted encoder system with 50 µm motion accuracy and a servo motor-driven extruder that can detect clogs or filament slips in real-time.

The AMS (Automatic Material System) was already the best in the market; now, this latest version includes airflow controls and electromagnetic vents that switch between drying and storage modes to keep filaments in top condition.

Heated and actively ventilated chambers are now standard for advanced materials. Where other printers need manual venting for PLA, or you simply just leave the door open, the H2D automates the process. For high-temperature materials like ABS or nylon, the chamber is sealed, and warm air recirculates it. For cooler filaments like PLA, top-mounted vents pull in and exhaust air. The chamber is capable of reaching up to 65°C, and when this is paired with dynamic airflow and filtration systems—it is especially useful when switching tool heads, such as when laser cutting generates smoke.

Where many machines handle each tool head in isolation, the H2D supports multi-process alignment. With the onboard camera (Laser Edition only), you can engrave on a 3D-printed part or cut printed/engraved objects with precision; all managed through the PC-only Bambu Suite software. I'm hoping a Mac Suite will arrive soon.

When it comes to those major differences between the Laser Edition and the standard H2D, it really comes through in the built-in safety hardware. The laser edition features green laser-safe windows to protect you during operation, and monitoring can also be done via the onboard HD camera feed. There are five flame sensors, an AI fire detection camera, and automatic emergency protocols—including retracting the head, closing vents, and sounding an alarm to suppress fires.

Precision remains a key feature. The dual nozzles operate from a single head, unlike IDEX systems, which means less moving weight and more consistency. Nozzle alignment accuracy is 50 µm, thanks to Bambu's eddy current calibration technology—which automatically compensates for filament residue and tool offset without any manual intervention.

The Vision Encoder Plate is another interesting option as it enables motion calibration using a specially marked build plate, which, when combined with temperature management and software features like auto-contour compensation, results in highly accurate, post-processing-free prints - something that I became slightly obsessed with due to the fine difference it makes.

Additional improvements include a new nozzle camera that monitors extrusion in real-time, catching spaghetti, clogs, and gaps before they escalate. The extruder now uses brushless servo motors, offering finer control over torque, speed, and positioning. With the standard hot end, the extruder delivers 40 mm³/s ABS flow rate; with the optional high-flow hot end, that increases to 60 mm³/s.

The AMS system has evolved again. AMS Gen 2 functions as both a dryer and a storage unit. It includes live humidity monitoring and keeps filaments sealed when not in use. For more advanced materials, the AMS HT is a dedicated single-slot module capable of maintaining up to 85°C and supporting low-resistance paths for tougher filaments like carbon fibre or soft TPU (90A TPU was used extensively in this test); the family all-know-how 3D printed shoes.

Network connectivity enables WiFi and LAN, and you can operate the H2D via Bambu Studio, Bambu Suite, or Bambu Connect (mobile and desktop). In an interesting move, if you do want to take the machine offline, you can opt for offline printing via USB or SD card. Developers can also access an MQTT port for third-party integration, making the H2D an ideal fit in custom production workflows. This is a major move for business as most of us have been speculating that Bambu Lab was moving towards a more locked-down and proprietary ecosystem.

As mentioned, this review is focused on the H2D Laser Edition, which is the fully featured version. While both machines support dual nozzle 3D printing, only the Laser Edition includes the laser safety windows, air-assist pump, birds eye camera, and additional tool heads as standard. These can be added to the base H2D as upgrades.

As for the heads themselves, the 10W and 40W laser modules offer clean engraving and cutting, while the digital cutter supports a pen holder for plotting. Each adds plenty of flexibility to the H2D and essentially makes it a great option for the office, workshop or classroom - the two areas where I think this will really appeal are for makers and crafters - just having all these tools in such a neat box is exceptionally handy.

Bambu Lab H2D: Performance

Even for everyday use, as a 3D printer, the H2D performs well beyond the capabilities of the X1 Carbon, no doubt in part due to the new AMS. The drying functionality, which keeps the filament in optimal condition before printing, makes a significant difference for a machine at this level.

In practice, these results are a noticeable improvement in print quality. Properly dried filament makes a surprising difference—far more than most realise—and the AMS ensures that filaments remain as close to the factory-sealed condition as possible.

But then, as you set up the H2D with the AMS 2, I quickly realised I could have up to five filament sources as standard, with the AMS feeding the right nozzle and external filaments feeding the left. Running initial single-filament tests, quality and speed matched the X1C closely. If you already own an X1C, the larger build volume would be one of two main reasons to upgrade; the other would be the fact of the superb dual nozzle tool head.

Things change significantly when using more than one filament, and not just because you now have an additional filament reel added to the mix. In one test that involved printing a two-tone frog using a single filament, this took just over three hours on both machines. However, switching to using two filaments, the H2D completed the print in 5 hours 27 minutes, while the X1C took over 12 hours, which is a massive leap in speed.

Advanced materials such as TPU and carbon fibre-filled filaments perform best when fed via a dry box into the left nozzle. Actually, TPU needs to be fed through that nozzle. While Bambu Lab provided both the H2D and the Laser Edition for review, they didn't include a single-slot dry box. So, it's worth pointing out that I used a Creality filament Dry Box unit to keep specialist filaments in the right condition.

Printing models like lamps, shoes, and GoPro mounts, the quality and finish were consistently excellent. The Autodesk Kickstarter model stood out not only for how good it looked out of the box but also for its dimensional accuracy, although there was a slight oddity that I have seen with other CORE XY machines. That is, the dimensional accuracy is superb, but a close look shows that the cylinders are not always completely round.

This level of precision is further supported by the machine's calibration plate, allowing users to fine-tune alignment. For most, the difference might be negligible, but for product design or production, it adds real value. The most notable enhancement that comes from using this plate is that it is absolutely round rather than very slightly oval, most notably in the benchmark test.

As with previous Bambu Lab machines, print quality proved to be excellent—but the more I used the H2D, the more I realised that print quality goes further. Being able to print two materials with that dual head enabled easy handling of a broader range of materials and made it more reliable than any of its predecessors. While dual heads have been used for years by other manufacturers and have been tried and tested, again here, they work exceptionally well.

That said, it's not all seamless. PLA support material, if not perfectly dry, caused problems during testing. One roll that had only been open a few days became unusable, while a freshly opened reel performed perfectly when kept in a dry box.

The machine's complexity also introduces occasional issues. The onboard AI camera will pause prints if it detects debris, spaghetti, or anomalies—even small ones—causing some workflow interruptions. It's effective but perhaps a little overcautious at times.

TPU loading is also a bit fiddly. To use it, you need to disconnect the Teflon tube from the external feed, guide the filament through the back, and then reconnect it—routing it manually. It's doable but awkward, especially if the machine is on a desktop, which is more for the positioning of the TPU box than anything. TPU must run through the right nozzle, meaning the AMS must be disconnected. In testing, the TPU 90A shoe print turned out especially well, with surprisingly durable results—enough to prompt several requests for printed footwear. Each pair takes around 70–80 hours to produce, and the machine handles the extended prints without issue.

Longer prints using support material were equally reliable, and the machine maintained consistent output over extended durations without intervention. Safety features help catch issues early, typically triggered by the appearance of loose filament strands of filament.

When it comes to print quality, there's no doubt that the H2D matches the excellent X1C and holds its own against the current crop of high-end 3D printers, including the PRUSA CORE One and PRUSA XL. The H2D's performance strength lies in multi-material printing, where it not only surpasses other multifilament printers but also outpaces Bambu's previous machines.

Of course, the H2D also includes laser engraving and digital cutting capabilities, though these require a head and platform swap. Switching to the digital cutter and plotter is the easiest: power the machine down, attach the cutter head to the front of the tool head, connect the cable, drop in the appropriate build plate, and power the machine back on.

From there, you can use the new Bambu Suite software on a PC to load a design, place it in the material, and start cutting or drawing. It's fast and relatively intuitive, making it ideal for craft work and creating stickers. With a 450 x 420 mm cutting surface, it can also handle A4 materials easily—great for cards, decals, or light packaging.

This really highlights how Bambu envisages this machine being used as a personal manufacturing and production machine, and for that, it's exceptionally well equipped. Just look at ETSY, eBay or one of the other similar platforms or go to a craft market, and you'll see countless laser cut and 3D printer objects; this machine enables you to take your creativity up to the next level with one machine that essentially does it all.

Then there's the laser module, which is more involved but still easy to set up. Both 10W and 40W modules are supported; attach the module, connect the cable, insert the laser build plate, run calibration, and you're ready.

Bambu Suite is well-designed and easy to use, although, at present, it is only PC based. It lets you assign engraving or cutting paths, split object sections, and quickly apply functions. Results are excellent—cutting is precise, and the motion control on curves and filled areas is particularly accurate, although I did find a slight ramping up of the power was required.

One note: Bambu Suite is currently PC-only. A Mac version is yet to be announced. During the test, I did attempt to connect LightBurn on Mac, but it wasn't compatible during testing. Although Bambu Lab has enabled some compatibility through third-party apps, there is some consensus that Bambu Lab is moving towards a more closed ecosystem, although at the same time, they have opened up the port for third-party connection, so we'll have to wait and see.

When it comes to using the output, the 40W laser does prove to be powerful and incredibly accurate. However, I did find that most materials required slightly deeper cut settings in the Bambu Suite than the default settings preconfigured in the application. For example, the 2 mm cork didn't cut through cleanly until I added another millimetre to the depth setting. This was a consistent pattern across various test materials.

Fill and line engraving, on the other hand, were immaculate—clean and accurate, even on intricate paths.

One limitation is the laser work area. If you're used to large-format cutters or engravers (e.g., A3 or 6–9 mm plywood), this space may feel tight. Many of my stock laser files were too large and had to be scaled or swapped for smaller craft projects. For small businesses, design prototyping, or hobby work, though, it's more than enough.

There's also currently no rotary option, so all material must lie flat. Still, the fact that this one machine combines 3D printing, laser engraving, and digital cutting in a compact, reliable platform is impressive. I did see in the interior that there are connection plug points, so this gives me the impression there may be more accessories to come.

Workflow complexity increases with advanced materials, especially during tool swaps or when managing dry filament feeds. Still, overall, the H2D handles everything with a level of refinement that I haven't seen with other multi-function machines.

Yes, there are a few compromises with the cutting and laser workspace size, but as a package, Bambu Lab has pulled off something quite special. For small to medium-sized multidiscipline projects, it works—and works well.

Bambu Lab H2D: Print quality

3D print Test 1

Dimensional accuracy - score of 4

Target 25 = X: 24.81mm / 0.19mm Error | Y: 24.89mm / 0.11mm Error

Target 20 = X: 19.87mm / 0.13mm Error | Y: 19.90mm / 0.10mm Error

Target 15 = X: 14.94mm / 0.06mm Error | Y: 14.91mm / 0.09mm Error

Target 10 = X: 9.89mm / 0.11mm Error | Y: 9.94mm / 0.06mm Error

Target 5 = X: 4.86mm / 0.14mm Error | Y: 4.86mm / 0.14mm Error

X Error Average = 0.126

Y Error Average = 0.1

X&Y Error Average = 0.113

Fine Flow Control - score of 5

Fine Negative Features - score of 5

Overhangs - score of 4

Bridging - score of 5

XY resonance - score of 2.5

Z-axis alignment - score of 2.5

Adding up the totals gives a final score of 28 out of 30.

3D print Test 2

Dimensional accuracy - score of 4

Target 25 = X: 24.78mm / 0.22mm Error | Y: 24.87mm / 0.13mm Error

Target 20 = X: 19.86mm / 0.14mm Error | Y: 19.89mm / 0.11mm Error

Target 15 = X: 14.86mm / 0.14mm Error | Y: 14.84mm / 0.16mm Error

Target 10 = X: 9.83mm / 0.17mm Error | Y: 9.84mm / 0.16mm Error

Target 5 = X: 4.86mm / 0.14mm Error | Y: 4.87mm / 0.13mm Error

X Error Average = 0.162

Y Error Average = 0.138

X&Y Error Average = 0.15

Fine Flow Control - score of 5

Fine Negative Features - score of 5

Overhangs - score of 4

Bridging - score of 5

XY resonance - score of 2.5

Z-axis alignment - score of 2.5

Adding up the totals gives a final score of 28 out of 30.

Bambu Lab H2D: Final verdict

The Bambu Lab H2D Laser Edition is one of the most impressive 3D printers (Multi Tool machines) on the market—and that's before you even consider its laser engraver or digital cutter and plotter. The ability to work with multifilament materials in a single print, combined with support for multiple AMS systems, makes it extremely versatile.

That said, it takes some time to understand how the filament feed works—how the AMS connects to the right nozzle and external filaments to the left—and how to match materials to a project within Bambu Studio. None of it is especially complicated, but it does require some careful setup. Once configured, the results are superb. I was genuinely surprised at the quality of the 3D-printed shoes, and many other prints would simply not have been possible without plenty of additional support material, even to this quality, although you can still see that this is 3D printed.

The machine feels like a continuation of what CEL-UK started with the RoboxDual before pivoting to B2B. The laser engraver and cutter are excellent additions, and while the overall package isn't cheap, it offers far more than most. For education, product design studios, or any professional setting needing a robust, flexible machine, the H2D is a superb fit.

One highlight for workshop use is the inclusion of laser-safe windows. With proper extraction, this can be used safely in shared spaces—something not always true with other engravers. The cutter, although the simplest of the three tools, is also the fastest and perhaps the most accessible—particularly valuable in education.

The updated AMS is a great improvement, though the curved top prevents easy stacking unless you build or print a custom shelving system, which still annoys me to a certain degree. With a flat top, these units could be neatly stacked while still allowing access to the filament bays. As it stands, I've had to improvise with three units awkwardly arranged on a rapidly disappearing worksurface.

On that work surface, something that I almost forgot during the test is that this is still a multifilament machine with two nozzles, so it still spits out excess from the back. Obviously, it was less than the single nozzle machines, but still, after a few weeks of testing, there was a good amount of filament behind the machine. The good thing here is that the machine is quite large and heavy, so you won't notice the pile until it starts to flow around the machine.

Across testing, using both the Laser and Standard editions, the print quality and usability remained much the same. The key differences lie in hardware: laser-safe green windows, the absence of a bird's eye camera on the standard model, and upgrade potential depending on your needs.

What stood out most during testing was reliability. Even with complex materials like TPU and CF over long prints, the machine ran without a hitch, the key being to keep your printer clean after each print. Otherwise, the AI will stop things and make you clean it out. Accuracy with PLA is good but takes a leap when paired with the Vision Encoder platform calibration.

What's interesting here is that while the scores in the benchmark tests are similar, both before and after the calibration, the real difference comes when you closely inspect the dimensional accuracy test. The smoothness of the cylinders and their positioning are significantly better after calibration than before, which you can hopefully make out in the images.

Ordinarily, the test models are printed with eSun white PLA; however, to easily differentiate between the two, I have printed the before in grey and the after in purple, as seen here.

If you're already using the X1C and want to take your multifilament printing to the next level, then the H2D is an obvious step forward. Add in the laser engraving, cutting, and digital plotting, and it becomes an even more attractive choice and ideal if you're looking for an advanced, multidiscipline machine.

Should You Buy the Bambu Lab H2D?

| Row 0 - Cell 0 | Row 0 - Cell 1 | Row 0 - Cell 2 |

Value: | The H2D is not cheap, but you're getting three machines in one—and as a 3D printer, it's easily the best multifilament printer currently on the market | 4.5 |

Design: | It's easy to see where Bambu Lab is going with this printer. While there are some workflow issues, the overall design works incredibly well. | 4.5 |

Features: | It doesn't make your tea or air fry your supper, but when it comes to features, it does just about everything else. | 5 |

Performance: | 3D print quality is as good as it gets, laser engraving is excellent (though a little limited in size), and the cutting/plotting is right in line with other dedicated machines. | 4.5 |

Total: | For education or product design studios, this is the machine to go for—letting you work with multiple materials in one small, efficient workspace. | 4.5 |

You need a single machine with multidiscipline.

The H2D offers superb 3D printing, excellent laser engraving, and digital cutting and plotting—all in one unit that fits on a standard work surface, reducing the footprint needed for three separate machines.

You need high-quality multi-material printing.

While the standout might be the tool-swapping capability, it's the ability to print with five materials—including advanced options like CF and TPU—that makes this especially well-suited for design studios and education.

Don't buy if…

Laser engraving is the primary focus.

The H2D laser is powerful and precise, but the bed size is relatively small—just over A4—which limits its usefulness for larger engraving or cutting projects.

You only need single-filament prints.

If you're not planning to use multiple materials, the more affordable X1C remains a great choice. It handles single-filament work just as fast—if not faster—and with identical quality.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.