TechRadar Verdict

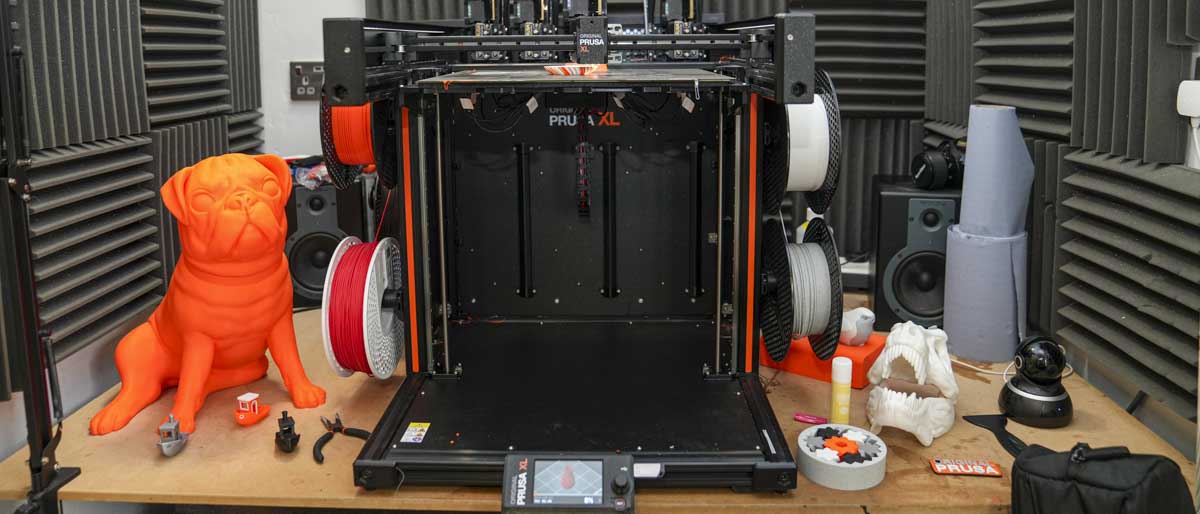

Despite the large print platform and the inclusion of a five-head changer, the Original Prusa XL's actual size while substantial doesn't actually occupy an excessive amount of space. Setting up the partially built machine takes around an hour, possibly longer, but this time investment proves worthwhile. Once operational, the multifilament machine comes to life with its CoreXY mechanics, delivering fast and the most accurate prints we've yet seen from a FFF printer. The precision of the multifilament head changer operates smoothly, avoiding the mess typical of other competitor multi-material machines. However, all these features and quality come at a quite hefty, but worthy price.

Pros

- +

Up to five materials

- +

Large scale printing

- +

Less mess than competitors

Cons

- -

No enclosure (yet)

- -

Time-consuming set-up process

Why you can trust TechRadar

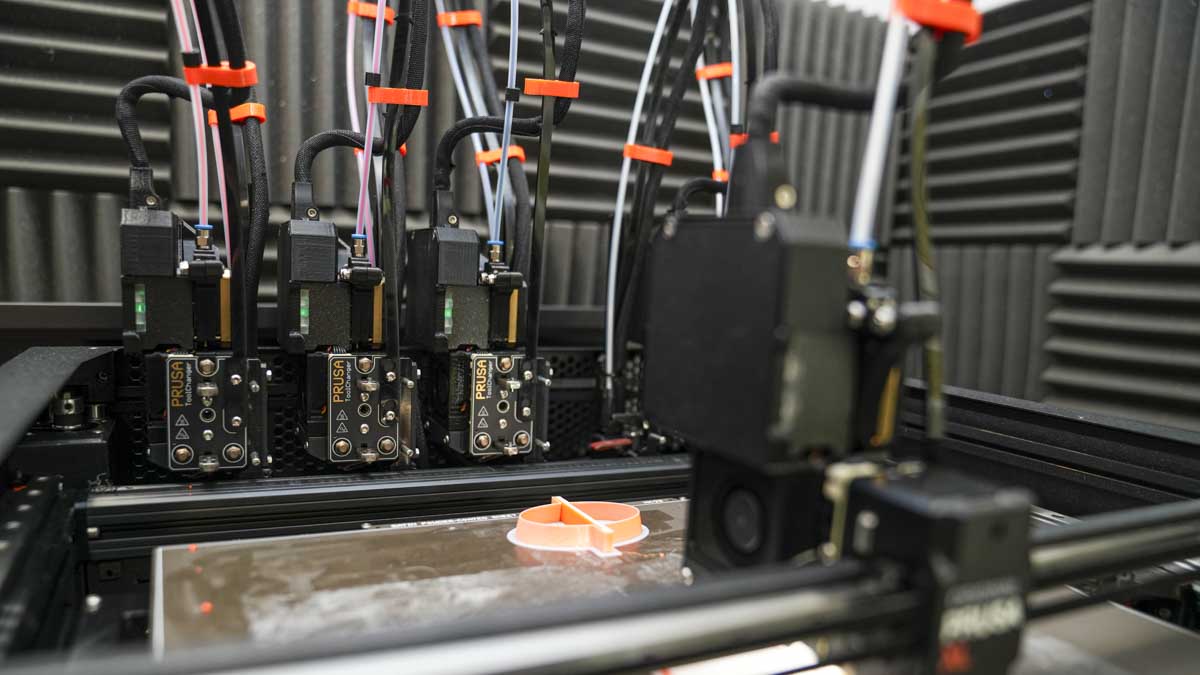

The Original Prusa XL is a colossal machine packed with innovative features that firmly place this filament multi-changer at the top of the desirability list. However, unlike the ultra-speedy Bambu machines with their multifilament AMS system, which tends to scatter filament offcuts everywhere, the XL is far more refined. Prusa Research has departed from the traditional single-head design and has opted instead for a multi-head approach. Although head swapping takes a few seconds, it's considerably faster than the filament switching used by most other systems.

While the multifilament ability should be a major feature of this machine, it is actually the sheer scale that makes it stand out. The print area is one of the largest of its type, and with Prusa Research and their machines now having an extensive reach into both the professional and enthusiast markets, this machine truly excels in terms of scale and features.

The Original Prusa XL is undoubtedly a pro-level machine, and this updated CoreXY printer marks a significant departure from the company's standard Cartesian design. The results are superb, but as with any large-scale 3D printer, the importance of the procedure cannot be overstated.. If everything is set up correctly, it's just a matter of ensuring your filament is in good condition, and the machine will handle the rest; if your filament is in the slightest bit out of condition, then the results, as with any of the best 3D printers, will be out.

Original Prusa XL: Design

As already mentioned the Original Prusa XL represents a significant departure from the company's tried and tested Cartestian bed-slinger design. Instead, it adopts the CoreXY mechanism and the latest firmware supporting input shaping, pressure advance, and precise stepping. The two standout features of this printer are its multifilament capability and its size. Although available in one--, two--, or five-head configurations, opting for at least two heads is highly recommended, with the option to add the remaining heads as the budget allows. In this 3D printer, review we've been able to go all out with the five head model.

This printer reflects Prusa Research's evolution as a major player in the open-source community. While the machine is available and nearly ready to use, it is also available as an open-source project, with files accessible on printables.com. Currently, there is no bill of materials, and purchasing the machine directly is likely easier and more cost-effective.

Design-wise, the XL is considerably larger than the MK4 in both physical size and print area—360 x 360 x 360mm compared to the MK4's 250 x 210 x 220mm. The CoreXY design features a rising build platform and a distinctive belt system. Notably, the machine includes an array of five-tool heads fitted to the back, a departure from the single-head MMU3 multifilament kits for the MK3 and MK4. This new design utilizes a single carrier that picks up one of the five-tool heads, uses it for printing, and then returns it before swapping to the next, minimizing filament waste between swaps.

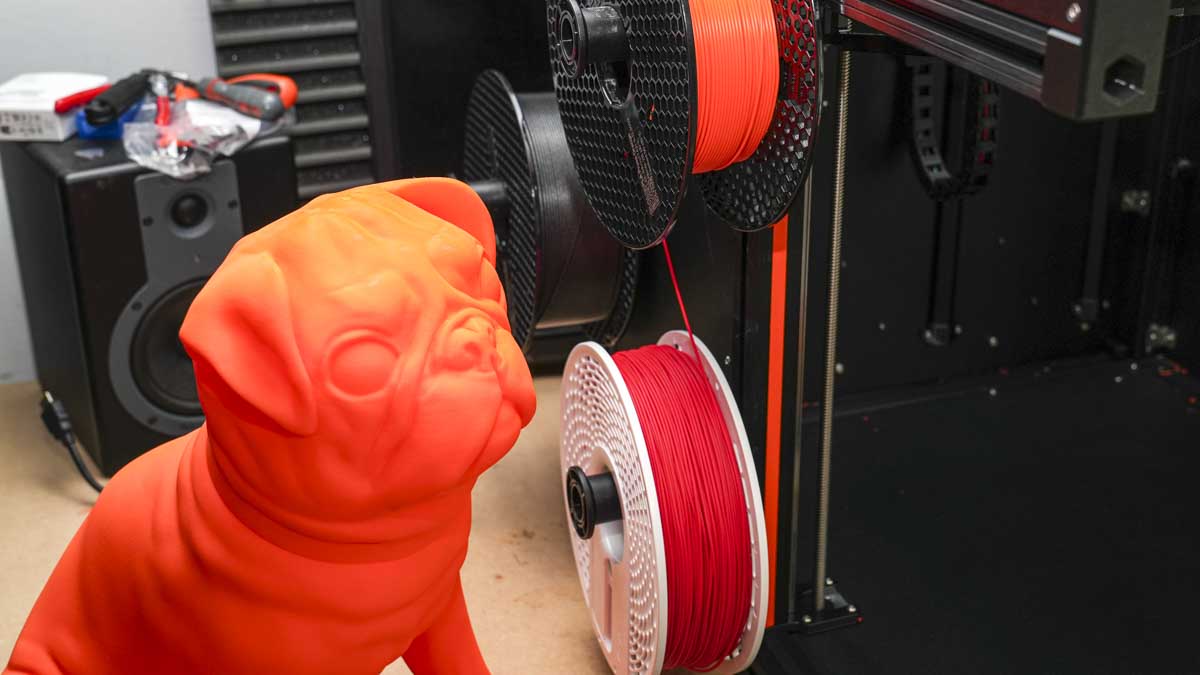

Filaments are neatly installed on the side of the machine, fed through filament sensors, and then into the tool heads, allowing for easy changes and updates. Each filament has its own sensor system to detect issues. If a head blocks, it can be taken out of action for repairs or replacement without pausing all work—a major consideration for businesses.

The print platform features the usual flexible bed to aid print removal, with different textures available. The heated bed underneath is segmented, heating only the necessary sections to save energy. Should any section malfunction, it can easily be replaced. Prusa offers a wide range of accessories and replacements, ensuring minimal downtime.

The control board maintains a slightly larger, initially analogue display with a click-and-rotate dial for navigation. While the dial approach is functional, you can switch to a touchscreen with a more modern interface through the interface.

For loading files, the printer supports direct wireless connections via the excellent PrusaSlicer software or through a USB key. Networking set-up requires some effort, but detailed instructions are provided, and once connected, the connection is strong and reliable.

Despite its size, the XL's footprint is surprisingly small, thanks to side-mounted reel holders. This set-up conserves desk space compared to other multifilament systems including that of the MMU3 and MK4, making its overall space requirement comparable to much smaller machines.

Original Prusa XL: Features

Feature-wise, the Original Prusa XL 3D printer stands out in the professional market with a unique approach that contrasts with the more refined and less modular designs typically seen. This adaptability, informed by extensive feedback from both enthusiasts and professional users, makes the XL a product shaped by actual user needs and demands.

The base model is relatively affordable, starting at around £2,000/€2,000, with the price increasing depending on the number of tool heads selected and additional future accessories, such as a full enclosure. This flexibility will be particularly appealing to professional outfits, as it enables you to tailor the machine to specific requirements. Additionally, as a Prusa Research system, it supports third-party updates and upgrades that are available for download from printables.com, allowing further customization.

At the core of the XL is a modular system that supports up to five independent tool heads. This set-up not only enables the use of up to five different colours of the same material or various materials in one print but also promises future expandability for specialist heads and is compaitible with the superb E3D V6.

One of the standout features, besides the five-tool heads, is the substantial build volume of 360 x 360 x 360 mm, making it one of the largest available for the price. The printer also features a selectively heated bed with 16 individually controlled segments. This design not only reduces power consumption when printing smaller objects but also enhances the machine's ability to manage different materials by providing precise temperature control for multiple models made from various materials.

Print Technology: CoreXY

Build Area: 360 x 360 x 360 mm (14.17 x 14.17 x 14.17 inches)

Minimum Layer Resolution: 0.4 nozzle that comes with the machine, the minimum is 0.1mm with a 0.25 nozzle, the minimum layer height is 0.05mm

Maximum Layer Resolution: 0.4 nozzle that comes with the machine, the maximum is 0.25mm with a 0.8 nozzle, the maximum layer height is 0.55mm

Dimensions: 800×800×900 mm (31.49" ×31.49’’× 35.43") side spool holders and top enclosure cover (Future addition)

Weight: 25.3Kg

Bed: Modular segmented heatbed with 16 individually controlled segments

Print Surface: Removable magnetic steel sheets with different surface finishes

Software: PrusaSlicer

Materials: Supports a wide range including PLA, PETG, ASA, ABS, and more

Print Speed: 400mm/s

First-layer printing is crucial, especially with multiple heads. The XL incorporates an advanced calibration system that includes fully automatic mesh bed levelling and skew axes compensation to ensure high precision. While the machine was pretty solid over the two-month testing period, we got into the procedure of calibrating the machine at the start of the week, which helped to ensure generally trouble-free printing.

The printer also includes several advanced features that are more common, such as power panic recovery, filament sensors, and advanced motion algorithms (Input Shaper and Pressure Advance), which are essential for maintaining high print speeds without compromising quality.

Like other PRUSA printers, the XL comes with removable magnetic steel sheets tailored for different materials, and a dab of glue stick is included for more challenging prints. The machine boasts wide material compatibility, and an enclosure is forthcoming to maintain a stable printing environment, which is especially beneficial for specialized materials. Although details about the casing are yet to be announced, the enclosure may include features like a heated environment with filters and possibly a filament drying chamber to enhance its utility further.

Original Prusa XL: Performance

It's important to note that the Original Prusa XL is a large-scale printer. Yet, it manages to maintain the precision typically seen in much smaller machines; essentially, it's a big little printer. When conducting benchmark tests with a single head, the machine focuses its heating and operations on a small area, achieving the speed and precision that one would expect from smaller counterparts.

A key to this high level of performance is the weight and rigidity of the XL, which significantly reduces the shake or wobble that can affect lighter, smaller models. This stability is crucial for effectively handling the speed and power of the motors and filament delivery. Initial tests displayed impressive accuracy, although there were some issues with surface finish and filament stringing in the first large print, this turned out to be due to the use of an older, exposed filament that was sat around for testing. After switching to a fresh reel, the surface quality of subsequent large-scale prints significantly improved, showcasing the importance of using well-maintained materials.

The environment and material handling are critical for the XL. Similar to best practices emphasized by teams like CEL-UK, maintaining filaments in optimal condition is vital. Once the enclosure is integrated into the system, it should further stabilize print conditions and enhance quality control. All subsequent prints in the workshop, using fresh or dried filament, showed that while small prints were not drastically different, the surface quality of larger prints was noticeably better.

The XL's performance is exemplary when printing with a single filament. The PrusaSlicer software offers comprehensive control over settings, allowing adjustments across three user modes tailored to different levels of experience. Switching to dual-filament printing for support and main build structures, the XL showcases its capability to handle complex models that might be challenging or frustrating on other machines.

The real advantage of multifilament printing isn't just the ability to use multiple colours; it's the capacity to combine different materials in a single print. For instance, PRUSA Research provides a test model of a small protective box, where the main body is printed in PLA, the locks are PETG, and the rubber weather seal is made of a flexible material. This multi-material approach allows the entire box to be printed as one piece but with functional diversity, such as lever locks and a watertight seal.

Continued tests utilizing mixed materials demonstrate the system's versatility, enhancing what can be achieved with the printer. The XL excels in overall print quality and speed, benefiting from the CoreXY mechanics. Filament swaps are notably quicker than other systems, and the print quality remains distinctly Prusa, achieving the highest benchmark results recorded to date at a perfect 30.

Original Prusa XL: Print quality

Dimensional accuracy - score of 5

Target 25 = X: 24.94mm / 0.06mm Error | Y: 24.90mm / 0.10mm Error

Target 20 = X: 19.88mm / 0.12mm Error | Y: 19.89mm / 0.11mm Error

Target 15 = X: 14.97mm / 0.03mm Error | Y: 14.93mm / 0.07mm Error

Target 10 = X: 9.90mm / 0.10mm Error | Y: 19.85mm / 0.15mm Error

Target 5 = X: 4.91mm / 0.09mm Error | Y: 4.89mm / 0.11mm Error

X Error Average = 0.08

Y Error Average = 0.108

X&Y Error Average = 0.094

Fine Flow Control - score of 5

Fine Negative Features - score of 5

Overhangs - score of 5

Bridging - score of 5

XY resonance - score of 2.5

Z-axis alignment - score of 2.5

Adding up the totals gives a final score of 30 out of 30.

Original Prusa XL: Final verdict

While the Original Prusa XL's cost may make it beyond the reach of many hobbyists, the MK4 and MMU3 options well-serve the enthusiast market. The XL, however, is primarily aimed at professionals or enthusiasts looking to upscale their projects. The design of the XL nods to the build-it-yourself ethos of the open-source community but presents a more refined version that can be tailored to user specifications.

Addressing some of the smaller concerns with the XL, one notable issue is the absence of an enclosure. Although one has been announced, details regarding its features—such as heating, filtration, or an integrated filament drying station—are still pending. Additionally, some standard features commonly found in enthusiast machines, like a camera for remote monitoring and a touchscreen interface, are not included but can be retrofitted with some technical skill, guided by online tutorials.

Another point of critique involves the tool head mounting system. Initial installation can be challenging, and while the tool heads generally secure in place adequately, the fittings may not feel robust over time, raising concerns about long-term reliability.

These are all but small issues, and in reality, the XL is a robust machine offering significant adaptability for both individuals and businesses. Out of the box, even as a single-head printer, it ranks among the largest and best solutions available in this price range. The multifilament capabilities and the efficient operation of the tool heads set it apart from competitors, including the ultra-fast Bambu machines, which target the enthusiast sector directly rather than professional.

The XL is unmatched in terms of accuracy and speed in its category. With the forthcoming enclosure and potential additions like a touchscreen and camera, the Original Prusa XL is poised to set a new standard for FFF printers in its price range, making it an exceptional choice for those seeking top level performance and adaptability.

| Row 0 - Cell 0 | Row 0 - Cell 1 | Row 0 - Cell 2 |

| Value: | Exceptional for professional use, somewhat pricey | 4.5 |

| Design: | Innovative and robust with modular flexibility | 4.5 |

| Features: | Advanced, versatile with smart multi-material capabilities | 5 |

| Performance: | Outstanding precision and speed, reliable | 5 |

| Total: | A top-tier choice for large-scale and multifunctional 3D printing | 5 |

Should You Buy the Original Prusa XL?

Buy if...

You're expanding capabilities

If you're planning to scale your printing capabilities with diverse materials and complex designs.

You want professional-grade print quality

For those requiring high precision and reliability in large-scale prints.

Don't buy it if...

You're on a budget

If the cost is prohibitive and the advanced features are optional for your projects.

You have limited space

If you need more space to accommodate its larger size and side-mounted filament reels.

We've also tested out the best laser engravers