TechRadar Verdict

Resin printers are really coming into their own at the moment, and although the GKOTwo has been around for a while, it still makes an impact when it comes to outright print quality. However, the price is steep, almost double that of other DLP resin 3D printers. As the testing progressed, it was obvious how much more this printer had to offer. Although there's no auto-fill—a feature that greatly speeds up the entire workflow process and helps you to keep on top of the use of resin—almost all other features you could wish for are here. The lid is hinged, so it's easy to access the build area, and both the build platform and tank are quick-release. The entire chamber is heated to ensure the best possible resin consistency throughout the print process. Uniformation has also added a filter to help keep the environmental air free from the usual smell of resin. Due to the high-resolution 8 K screen, print quality is as good, if not better, than that of most DLP printers. As ever with resin printers, workflow is time-consuming, with the printing, washing, removal of supports, and curing process all adding time. The results are superb, and considering the recent price drop, this is an outstanding printer that sits at the top of the DLP print models before you leap to the laser.

Pros

- +

Exceptional build quality

- +

High-quality prints

Cons

- -

No autofill

- -

No live remote monitoring

Why you can trust TechRadar

The Uniformation GKtwo has made an impact in the market with its speed and quality, distinguishing it from other cheaper DLP models. It is essentially a standard 8K resin printer that uses an LCD panel to cure the resin.

What has marked this printer out against some of the best 3D printers we've seen in a fairly crowded market is the build quality and high-resolution screen. However, the competition is catching up, with many of the high-end features that help ensure superb print quality. This printer is now capable of appearing on cheaper machines.

Still, the machine's size and weight reinforce its absolute build quality. Once you get into the full resin workflow, which is often messy, Uniformation has the full ecosystem of wash and cure machines that enable you to keep that mess to a minimum.

The GK Two is also one of only a few machines that feature a heated build chamber and air filter, each of which performs an important function when it comes to where you can use the printer and ensure the best possible print quality.

However, the point remains that, with other 8K machines now available for far less, is spending that additional capital really worth it?

Uniformation GKtwo: Design

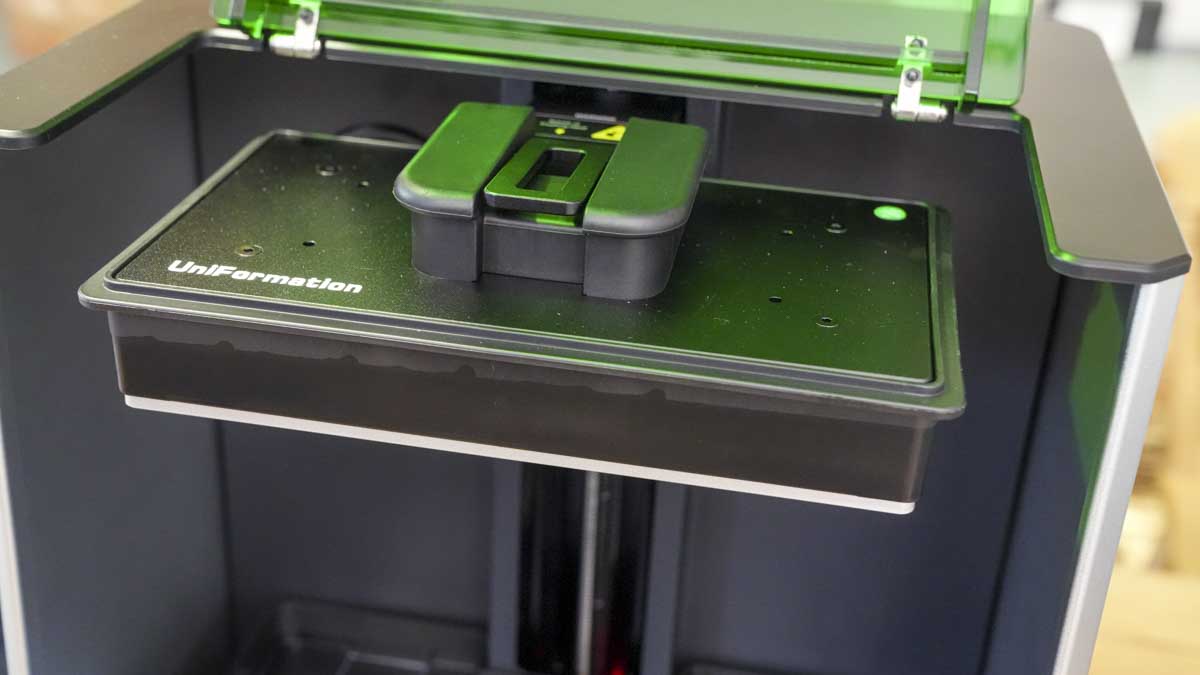

The GKtwo is a distinctive-looking machine, measuring 350x315xH455 mm and weighing in at some 20 kg, with a large green flip lid that covers the large build area. The lid serves a dual function: it protects the user from the UV light used to cure the resin and protects the resin from ambient UV light, which may inadvertently cure the resin when not in use. Like many machines, the lid is articulated with a rear hinge, allowing it to be easily flipped up for access to the build area. While there are still a few resin printers with completely removable lids, this solution is by far the best.

The lid covers the main machine, which features a large metal base with a touchscreen on the front, connection ports around the back, and the resin tank and build platform inside. The design follows the usual conventions, with the build platform dipping into the resin tank before being exposed to build up the model.

Sign up to the TechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

The build platform is all-metal and fixed with a quick-release lever that secures it firmly in place when mounted to the Z-axis. The platform itself is uncomplicated and is fixed metal with no quick-release mechanism for the prints, so, as is common with resin printers, a scraper can be used to help remove the print after it is finished.

The resin tank sits on the base of the machine and covers the 8K LCD screen. A nice touch here is that the tank is also quick-release, so it can be removed quickly for cleaning when needed. Unlike some of the latest machines, this tank needs to be manually filled to level before printing.

An increasingly common feature is the heated inner chamber and filter; these are both incorporated into the design rather than being add-ons, so they sit neatly and securely as part of the system.

Overall, the design is solid and high-quality. Parts are easy to access and clean, and the design has been carefully thought out to ensure easy operation. Although the design is good, one aspect that could be improved is adding an auto-fill feature for the resin.

Uniformation GKtwo: Features

The size and weight of the machine instantly give this 3D printer a premium look and feel, making it one of the largest DLP printers available within this price range. Opening up the lid reveals a printing volume of 228x128x245mm, which, for most enthusiasts and modellers, will be a perfect size for most creations. Jewellers and product designers will also benefit from the slightly larger-than-average build volume.

Print Technology: Photocuring LCD

Build Area: 228 x 128 x 245 mm

Minimum Layer Resolution: 0.03 mm

Maximum Layer Resolution: 0.1 mm

Dimensions: 350 x 315 x 455 mm

Weight: 20 kg

Bed: Heated

Print Surface: Quick-release design

Software: Compatible with Chitubox; Gktwo Slicer

Materials: Resin

Print Speed: 2-3 seconds per layer at 0.05 mm

At the heart of the machine is the photocuring 8K LCD screen that enables a curing time of 2-3 seconds a layer at 0.05mm layer height, using a wavelength range of 402.5-405nm. This means that the printer has wide compatibility with most standard 3D print resins.

When it comes to transferring prints to the machine, the simplest way is by means of the USB port, although it is also possible to send the files across using the WiFi connection. To do this, however, takes some knowledge of the Prusa slicer network settings. When it comes to the slicer software used with the printer, Uniformation has adapted a version of Prusa Slicer, which, as always, works smoothly.

However, for some users, the advanced details of that application can initially be a little daunting. However, once you get your head around the options, the control and ability to adjust supports make this one of the most finely tuned options for resin printing out there, aside from PreForm, which is only compatible with Formlabs SLA printers. Although Uniformation ships the printer with GKtwo Slicer, you also have the choice of using the excellent Chitubox.

The UniFormation GKtwo has already garnered quite a following due to the machine and print quality. In use, the machine is simple to set up, and throughout the test, absolute reliability was a key feature; as long as you check the resin tank for any debris, ensure the build plate is clear, and obviously keep the resin tank topped up.

During the print process, two non-print-related aspects really stood out with this printer. The first was the smell or lack of it. The UniFormation GKtwo has a built-in filter unit, which seems to work overtime to ensure that the room you're printing in remains as resin-smelling-free as possible. Throughout the test, this really seemed to be the case, and compared with other systems out there, which are a little plug-and-play, this is simple and fully integrated.

The second is that the printer works without issue, even in cold weather. While the temperature outside dipped below 0°C, and conditions in the workshop weren't much better, the printer continued to produce outstanding prints without issue. This is due to the heated chamber, which helps to ensure that the print environment is always at an optimum.

Uniformation GKtwo: Print quality

When it comes to printing, the slicer software is based on PRUSA Slicer, so while it can be a little complex to get into initially, it does give you a huge amount of options over the quality of the print. More importantly, it gives you plenty of control over the support tree structure, which helps you get better-quality prints as they're adjusted from the standard settings.

Moving to the machine and the print workflow, once the model is uploaded through either USB or the Wi-Fi connection, you can then just leave the machine to get on with the print. The speed of the machine is also something to note, with prints being produced at a decent speed compared with printers from a year or two ago, although more in line with the most recent crop of machines.

The print quality itself is outstanding once the prints have been properly cleaned and all supports removed. Through the test, I used a generic resin, which proved to be a little brittle and made it difficult to remove some of the support structures with some prints. While the resin was brittle, it was a high-detail option and gave a superb surface finish to the models. The trick here was to remove the prints from the machine as quickly as possible after the print process, wash them for around ten minutes, and then remove the supports before curing. This issue is purely down to the type of resin used rather than the printer.

At 8K, this isn't the highest-resolution printer out there; however, the quality of the surface and the detail really stand out, making this a great choice for model makers and jewellers who need intricate detail in their prints. Dimensional accuracy for the functional parts made was also good, showing that, again, this is a printer that could be used for prototypes and small production runs.

Overall, the print quality from the UniFormation GKtwo is some of the best that I have seen from a resin printer. With the recent price drop, this printer is somewhat of a bargain, if still a little more expensive than some of the competition.

However, there are several points that you find when using the printer, which means if I had the money, then the Form 3+ is definitely the printer that I would opt for without a doubt. It's also the printer that I would recommend for any business needing a production-quality model.

The first of the points around performance is the workflow. While other printers are quickly catching up, they're still far from the absolute ease of use. The cartridge system is simple, as is the tank design; you literally insert it, and then you're ready to go. Likewise, there's no faffing around with adjustment; the machine does everything on that front for you, including filling the tank and making sure that the temperature and consistency of the resin are correct for the best possible quality print.

Once the print has finished, the platform releases easily, and being the build platform 2, a quick push of the handles and the print pops off without the usual battle to release the print. Then it's just a case of dropping into the Form Wash, removing the supports, and then into the Form Cure to finish.

Essentially, Formlabs has created an entire ecosystem that makes the process as mess-free as possible, although eliminating all the stickiness isn't quite yet possible.

Once the print has fully dried, it can then be worked so that if there are any remnants of the support structure, these can be removed with a file, snips, or knife. Generally, the prints came out relatively clean and ready for use. One of the main projects for this project was to create a focus bracket for an Arri Alexa follow focus; this required absolute accuracy, although simple. This proved to be a simple enough project for the printer in one of the tough materials and was immediately put to use.

Likewise, other functional parts were easy to make and support with the Light-Touch Removal Supports that are generated by the software, holding the model firm during the printing process and then ripping free relatively easily once the wash process is complete. Under a bright light, the prints can then be inspected and cleaned before curing. I found that once the wash had been completed, I would remove the supports, brush away any support debris, and then give another quick wash before curing.

If any supports are left in place during the curing process, then on some models, they're almost impossible to remove due to the strength of the materials.

When it came to detail, these models showed a quality and level of detail that no FFF printer that I have used can come close to competing with. Even the best of the LCD printers with their high-resolution screens are left behind when the printer is switched to the highest quality setting.

The surface finish and detail are also exceptional, and while you do have to clean up the prints to a greater degree than with many FFF models, the quality is just outstanding. For me, the real advantage of Form 3+ is the Light-Touch Removal Support. Unlike other printer software that creates support structures that are almost impossible to remove, the PreForm software enables you to balance the support structure perfectly.

While this is aimed at the professional market and businesses such as architecture, engineering, jewellery, film, and many more, this printer will also benefit model makers and other craft enthusiasts looking for absolute quality and precision.

Uniformation GKtwo: Final verdict

The UniFormation GKtwo is a high-resolution 3D resin printer with an incredible amount going for it. Firstly, the high build quality stands out, and it packs in all the features you would expect from commercial-end resin printers rather than the consumer end, which is where the machine's cost places it.

The photocuring LCD at 8K is one of the higher-resolution screens out there but is by no means the highest, with a good crop of 12K options appearing at present. However, even against these new machines, the information GKtwo holds its precision and quality of surface that makes it stand out.

Features such as the screen, the air filter, the flip-up cover, and the heated inner chamber boost the overall performance and help ensure the high print quality and reliability that this printer is capable of.

As with any resin printer, the machine and the print are just the start of the process, as there is the whole wash and cure process to contend with once the print has finished. At this point, there is no quick release from the platform for the print, while the platform itself is quickly released from the machine. Uniformation does produce a wash and curing machine, which I used throughout the test; like the resin printer, the quality of this is excellent, and as always, it's worth purchasing.

If you need a resin 3D printer that produces high-quality prints with an excellent surface finish, the UniFormation GKtwo is a great choice. It's also a good option if you need to use the printer in a large room where you'll also be working or a cold workshop or room where temperatures might dip.

Should You Buy the Uniformation GKtwo?

Buy it if...

You value print quality and features

If high-resolution prints and advanced features like a heated chamber and air filter are priorities, the GKtwo's exceptional print quality and robust feature set make it a standout choice, despite its higher price point.

You're a professional or serious hobbyist

For those needing a printer that delivers consistent, detailed results for professional prototypes or intricate hobbyist projects, the GKtwo's precision and build quality justify the investment, especially in a larger workspace or cooler environment.

Don't buy it if...

You're working to a budget

If cost is a major factor, consider other options. The GKtwo's premium price might be hard to justify when more affordable DLP resin printers are available that still offer decent print quality and necessary features.

You want convenience features

If you prioritise ease of use and time-saving features like auto-fill and live monitoring, the GKtwo might disappoint. Its lack of these modern conveniences could be a dealbreaker for users seeking a more automated 3D printing experience.

We tested the best 3D modeling software - and these apps really bring creations to life

Alastair is a photographer, filmmaker and tech writer who has been working in the publishing industry since the late 1990s. For more than 25 years he has covered photography, video and technology across Future's photography, technology and gaming brands. He runs a photography and video production company and lectures in TV and film. He can usually be found testing mini PCs or prototyping and prop building with the aid of 3D printing.