TechRadar Verdict

Built with over 50% of 3D printed parts is a confident move, as is sticking with LulzBot's long held ethos of uploading all plans to the company's GitLab site. Still, this openness pays off with a machine that excels and reflects its Open Source origin. In use, the Taz Sidekick 747 is every part LulzBot, a workhorse that's ready to print with precision and reliability. Print quality is superb, and with customizable options alongside plenty of room to tinker, this is a printer that supplies quality and enjoyment at every level.

Pros

- +

Open-source plans

- +

High-quality prints

- +

Strong reliability

Cons

- -

BL Touch sensor can be temperamental

Why you can trust TechRadar

Specs sheet

Print Technology - Fused Filament Fabrication

Print Volume - 231mm x 231mm x 248mm (9" x 9" x 9 1/4")

Ambient Operating Temperature - From 5°C to 45°C (41°F to 113°F)

Operating Footprint - 24"x28"

Leveling - Genuine ANTCLABS BLTouch ®

Connectivity - USB Serial and Included 8GB SD Card

Print Surface - Borosilicate Glass with PEI surface / Magnetic Flex Plate System

Maximum Print Bed Temperature - up to 120°C / 110ºC

Layer Resolution - 0.05 mm - 0.5 mm (0.002 in - 0.020 in)

Filament Diameter - 1.75mm or 2.85mm (See Tool Heads)

Supported Materials - Open filament system compatible

Operating System Compatibility - Windows, GNU/Linux

Recommended Software - Cura LulzBot Edition - Version 3.6.25 or newer

Firmware - Marlin

Supported File Types - .stl, .obj, .x3d, .3mf, .png, .jpg

Print Volume - 231mm x 231mm x 248mm (9" x 9" x 9 1/4")

Not long ago, it seemed LulzBot and its workhorse 3D printers would disappear. Thankfully, Fargo Additive Manufacturing Equipment 3D stepped in, and not only did it buy the company and continue with the Lulzbot brand, but also thankfully retained its open source ethos.

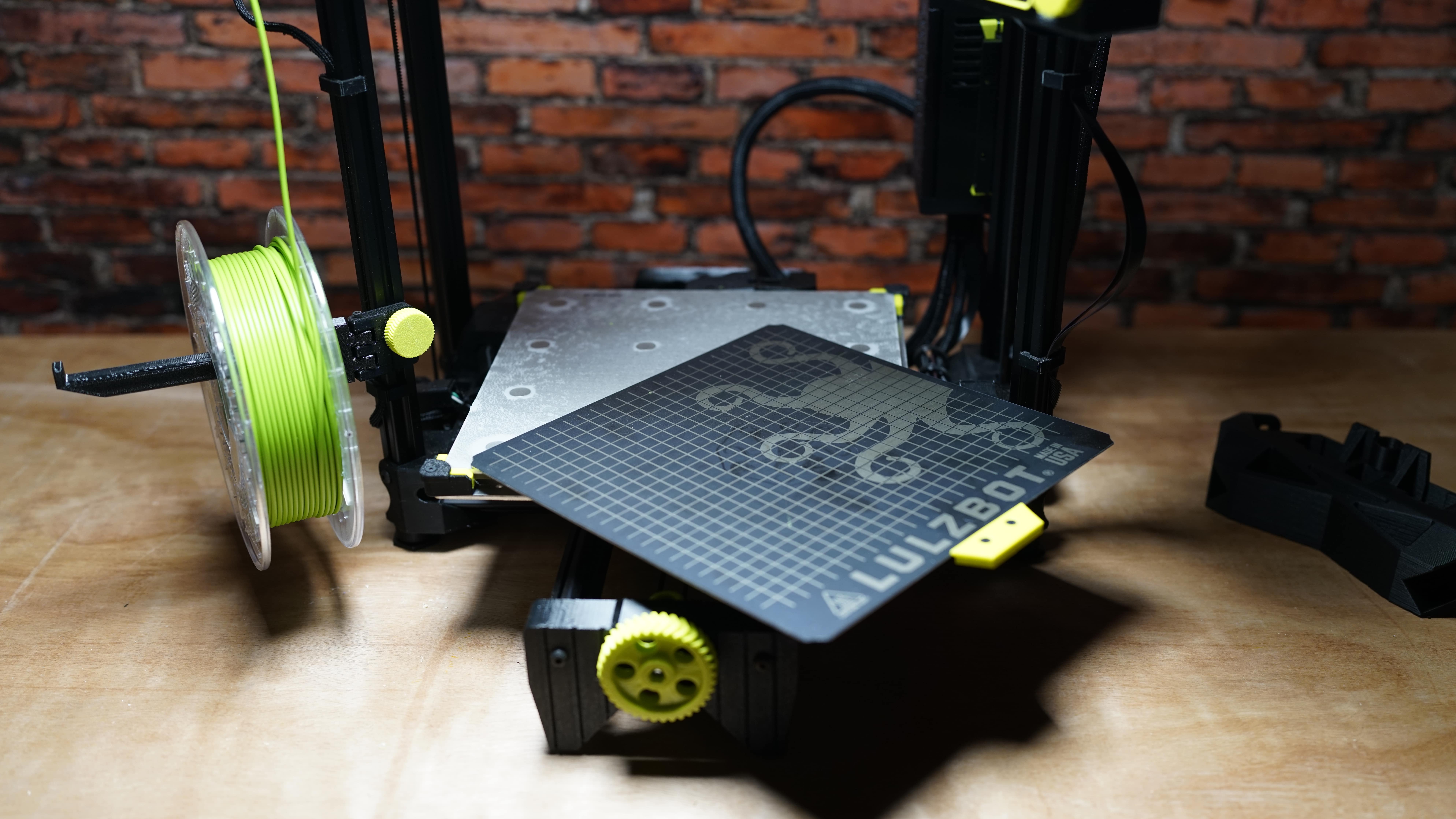

If anything, the company has stepped up its printer design and its connection to the open source community. The new printer not only features more printed parts than any other printer that we've ever seen or used, but all the plans and STL files are available online for users to download and print for free. In theory you could download the 3D print files and essentially print over 50% of this printer yourself, in practice once you’ve purchased the filament and all the electronics, it's actually cheaper to buy the 3D printer directly from LulzBot!

Open source doesn't just manifest in the fact that the plans and files are online. The firmware utilized for this printer is Marlin, a freeware option used by many 3D printers. It enables Slicer applications such as PRUSA Slicer and CURA to send the commands needed to print the 3D model. So, for anyone wanting to customize the machine or software to their way of working, a little tinkering will quickly get you and your machine to where you want to be.

To that end, the SideKick is a cartesian axis system 3D printer offered in two sizes, the Lulzbot Sidekick 289 and 747. Both are fully configurable at the point of purchase, with a range of tool heads and options that can be added. The basic kit for the Sidekick 289 starts at $795, and the SideKick 747 costs $995, so you can adapt and upgrade the printers if and when your budget allows.

In this review, we've opted for the SideKick 747 with a few essential but small additions over the base model; these include SK285 Tool head $195 (2.85mm filament rather than 1.75mm), Magnetic Flex Plate System $40 (Glass is the $0 option so this is a well spent $40), LCD Controller $95 (Basic but the standard option is a direct cable to your computer, Filament run-out sensor $20 (Cheap and for larger prints will save you pain), the total cost at present $1345.

Design

As mentioned, the Lulzbot SideKick 747 follows the cartesian axis system design of 3D printers. This design essentially has the tool head move on the X and Z axis, while the print base moves on the Y axis, and has been proven accurate and robust over the years, with the likes of PRUSA, CEL-UK and AnyCubic also using this design style.

The product takes around 10 minutes to assemble before switching on and starting the first print. Assembly requires that the base mechanism is bolted into place, the tool head installed, and a few wires are connected. Clear instructions in the box should be carefully read before assembly, and as the machines are built in the US, it's important to switch the power supply option from 120 to 240V if you're living elsewhere

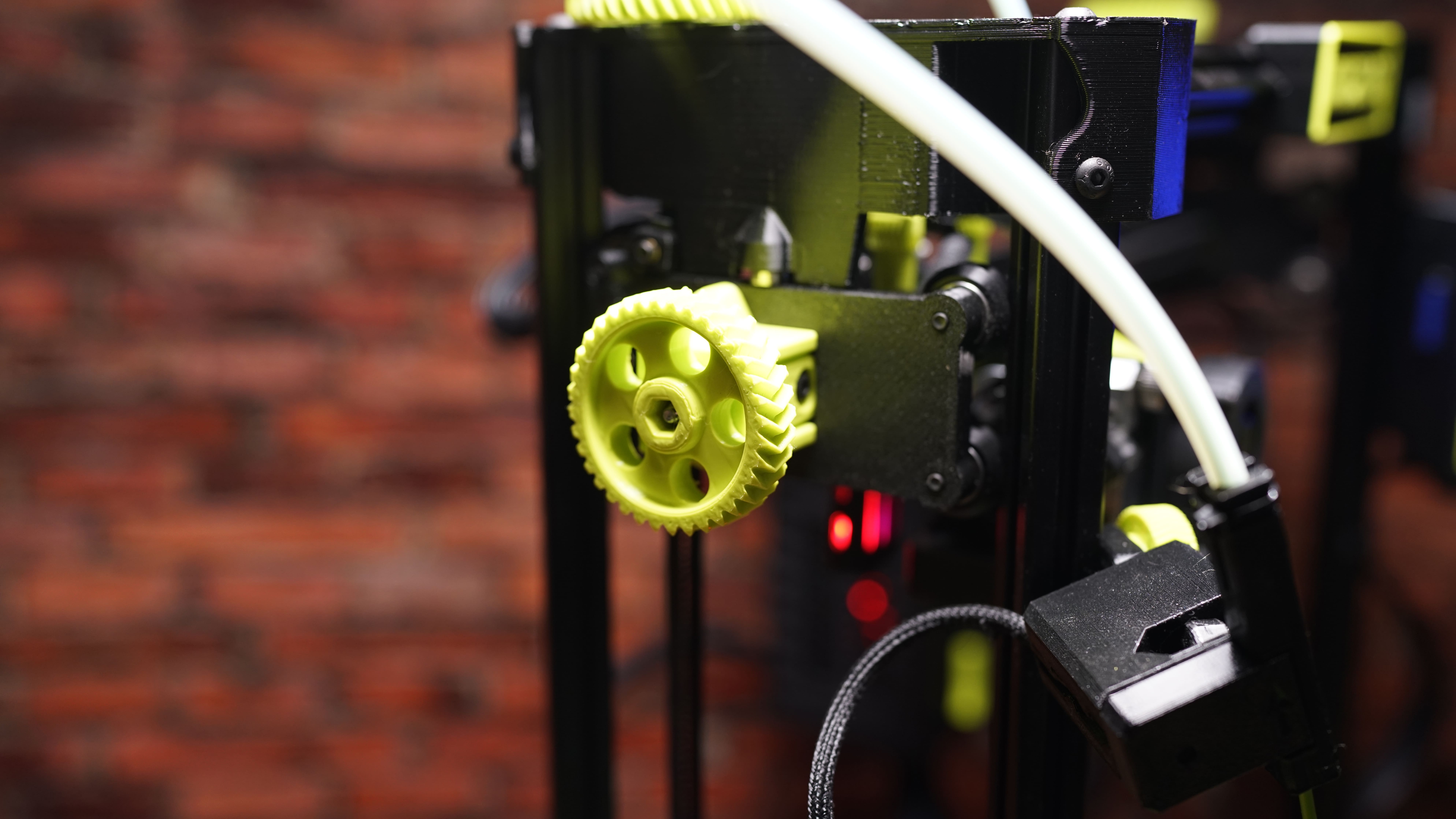

The machine sports an opendesign, with aluminum tubing and 3D printed parts making up most of its structure. Even the tool head, power supply cover and control board feature 3D printed parts, and are testament to the quality of this printer.

As the printer design is open everything is nice and accessible - however, it does also mean you must be careful with the ambient temperature when printing high-temperature materials such as ABS.

Regarding materials, the standard print heads will enable you to print with all common materials, including ABS, PETG, PA, PC and TPU.

Through the configuration of your printer, you can go for a stripped-down version of the machine with just the basics to get you started. While this will provide you with a very proficient machine, the addition of the controller, filament run-out sensor and Flexi base plate all help make life easier.

Features

The review model we used had been tweaked in the configuration slightly, with the standard tool head at 2.85mm, controller and filament run-out sensor. However, this machine has been designed to suit the user's needs rather than the use being 100% prescribed by the manufacturer. The other basis of the printer is that it can be upgraded in many ways, either through the addition of tool heads or through the huge amount of information and feedback you can get through the open source community.

As such, there are functions and features that we wish were on the LulzBot SideKick 747 but aren't, and are not available as purchasable additions. However, look online or use your expertise, and you'll be able to adapt the machine to add Wi-Fi and other features if desiredt.

Sticking with what is provided, the machine features a more than 50% 3D printed construction, with the main frame being aluminum tubing, creating a surprisingly compact and solid machine.

Our review model shipped with the SK285 0.5mm nozzle, and this can reach a very respectable 290º. The design of the tool head is modular, with three screws holding it in position and a single cable. If you want to change the tool head, then all you need to do is undo the bolts, pop in the new head, update the software through CURE LE or the controller, and you're set to go, with the entire process taking no more than five minutes.

The Magnetic Flex Plate System matches the temperature of the SK285 tool head, which can reach temperatures of 110º if required. When it comes to bed leveling, a BL Touch sensor is used; as the machine starts each print, multiple points across the print surface are tested to ensure everything is level. Once configured, this is incredibly accurate.

The filament run-out sensor is a worthwhile addition and pauses a print if the filament breaks or runs out - and at $20, could be essential.

The controller is another optional extra and enables you to use the machine without connecting to a computer. It features an SD card slot so models can be loaded in ready for printing, and a simple interface lets you flick through options and settings.

Regarding the all-important build volume, the SideKick 747 offers 231mm x 231mm x 248mm and a print resolution of 0.05 mm - 0.5 mm. The printer is compatible with PLA, Natural and Metal PLA Blends, TPU, ABS, PETG, nGen, INOVA-1800, HIPS, HT, t-glase, Alloy 910, Polyamide, Nylon 645, Polycarbonate, PC-Max, PC+PBT, PC-ABS Alloy, PCTPE, and more.

Performance

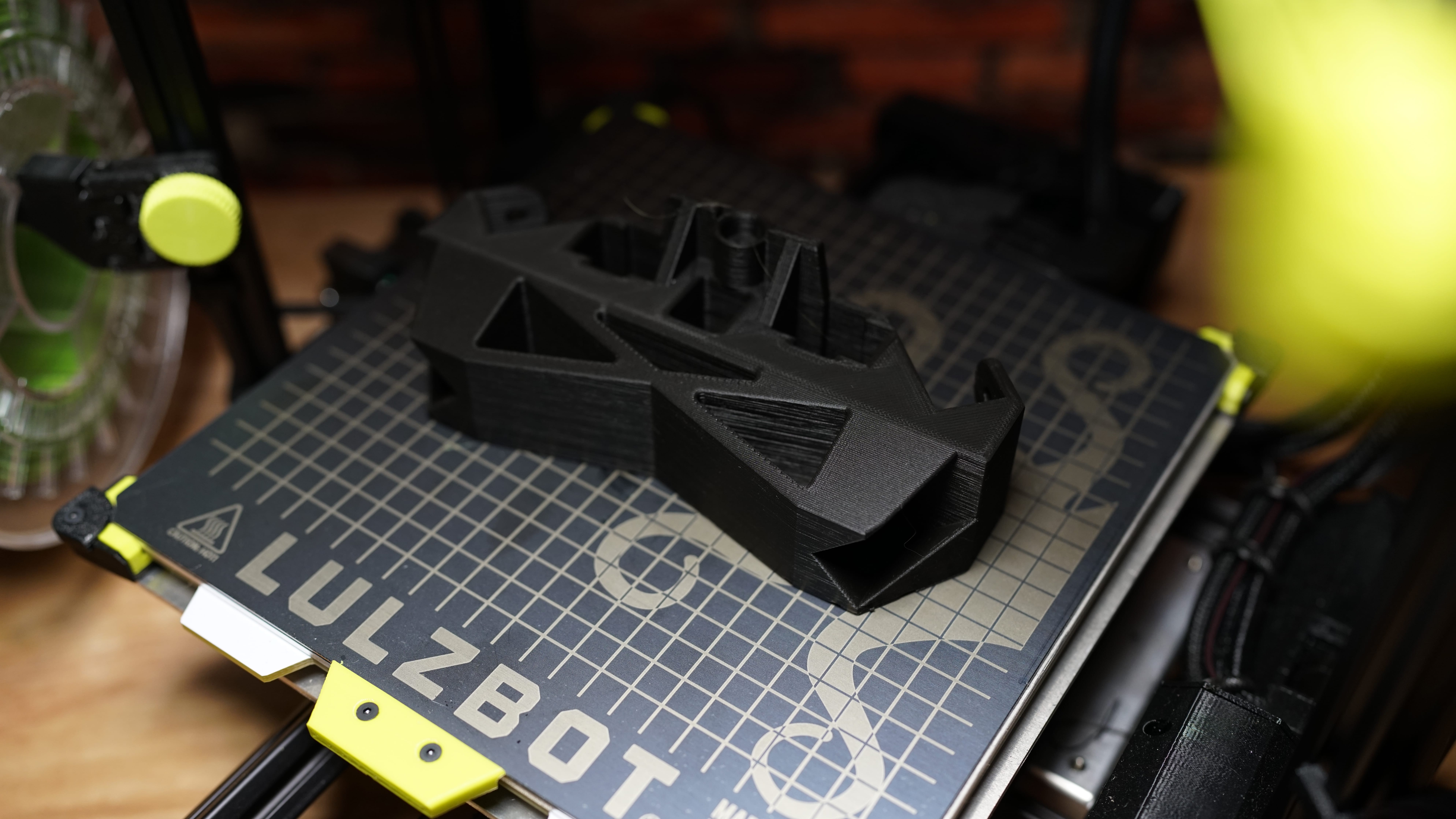

After assembly, the first few prints required a small adjustment of the Z-axis to ensure that prints stuck to the build plate. Every print thrown at the printer, from vase to camper van table, was printed without issue.

The print volume was more than adequate for most models, and some tweaking of the settings enabled multiple clean PLA prints that both showed the accuracy and quality of finish.

As with previous Lulzbot printers, we were incredibly impressed with the layering quality. It's consistent, and the filament laid down through the X and Y axis is smooth and accurate.

One thing that makes the Lulzbot stand out when compared with cheaper printers is the consistency. If you want a quick draft print, that's exactly what the SideKick 747 provides. It not only prints quickly at a lower resolution but creates that print with consistent quality. OK, you can see the layers, as it's a low-quality draft print after all, but there are few if any breaks and the quality is consistent.

At the other end of the scale, considering the relatively wide 0.5mm nozzle, the quality of the finely detailed prints is equally impressive, with smooth walls and fine detail. Saying that, with the 0.5mm nozzle, it's a good all-rounder balancing speed with detail, and the other tool heads offer finer detailed options if you want to print detailed models or fine detail - or if you’re printing prototypes and parts.

When it comes to the finer quality, the printer is accurate, but the larger diameter nozzle does limit that detail, and this is when the speed of the tool head change comes into play - keep in mind we only looked at the SK285 Tool head with this review sample.

Regarding prints, CURE LE and the Lulzbot SideKick communicate well. The time estimations given are relatively accurate if you set aside the initial warm-up and bed leveling process that takes five minutes.

Taking the three print qualities printing the test model 3D Benchy the times weigh up as follows:

- Draft estimate 41 minutes actual 45 minutes

- Normal estimate 65 minutes actual 75 minutes

- Fine estimate 120 minutes actual 140 minutes

The overall performance of the Lulzbot SideKick 747 is excellent in real-world tests; here's how it fared with the benchmark tests.

Print Quality

Dimensional accuracy - score of 5

Target 25 = X: 25.02mm / 0.02mm Error | Y: 25.03mm / 0.03mm Error

Target 20 = X: 20.05mm / 0.05mm Error | Y: 20.06mm / 0.06mm Error

Target 15 = X: 15.07mm / 0.07mm Error | Y: 15.09mm / 0.09mm Error

Target 10 = X: 10.11mm / 0.11mm Error | Y: 10.21mm / 0.21mm Error

Target 5 = X: 5.15mm / 0.15mm Error | Y: 5.18mm / 0.18mm Error

X Error Average = 0.08

Y Error Average = 0.11

X&Y Error Average = 0.1

Fine Flow Control - score of 2.5

Fine Negative Features - score of 4

Overhangs - score of 3

Bridging - score of 5

XY resonance - score of 2.5

V - score of 2.5

Adding up the totals gives a final score of 24.5 out of 30.

Verdict

The Lulzbot TAZ SideKick 747 is the first big redesign from the company under its new ownership, and there's no doubt that it is a great machine. What is surprising is that it's more LulzBot than ever; as you're using the machine, you can feel it has closer ties to the open source community than any printer the brand has previously released. It's also worth mentioning that if you have an issue with anything, the company's support goes above and beyond in helping you resolve it.

In use, the printer is almost completely plug and play. With the customized version of CURE LE (Lulzbot Edition) ready to go, there's no need to self-configure the software or work out different profiles, meaning that from the outset, you can print decent quality prints.

We loved the design and the pure volume of 3D-printed parts. The few upgrades, such as the filament run-out sensor and the flexible magnet bed and control module, are worthwhile additions to the basic package, but it's nice that you can get this printer for cheaper and upgrade as you need.

The one aspect that did cause a few issues at the start was the BL Touch sensor. However, the machine ran smoothly once adjusted using the small grub screw at the top.

While the machine is excellent, we would have liked to have seen a couple of additions. The first is for Wi-Fi connectivity, a feature still lacking on many 3D printers, but it isn't easy to step back once you have it. Likewise, we would have liked to have seen a touch screen interface rather than the more primitive control wheel style - the control module works well, but it does feel dated.

Otherwise, the LulzBot TAZ SideKick 747 is a superb machine that will provide you with many years of happy printing, whether at home or in the workplace. For those that want to print, the SideKick 747 is solid and reliable with the features that will ensure you get the prints you need. Best of all there's plenty of options to swap the tool heads to meet your exact needs. This is a superb base for those who like to tinker and expand on a machine's function and features, and makes the Lulzbot TAZ SideKick 747 one of the best 3D printers currently available.